Applications

FOOD & BEVERAGE

Many of our filtration technologies were first developed for beverage applications such as clarification, bacteria reduction, sterilization, and stabilization. Today, FILTROX is recognized as the leading supplier of filtration systems in many beverage segments like wine, beer, sprits, cider, tea, fruit juice and soft drinks.

WINE

The filtration of wine has been a main focus of our activities since the beginning of our company in 1938. We are proud to be a supplier of many of the world’s most renowned wine producers.

Our depth filter sheets are used in a wide range of retention rates for the filtration of wine. The range covers coarse filtration, clarifying filtration to sterile filtration, or for removal of TCA, TBA and TeCA from wine.

We offer a wide variety of high quality plate and frame filters for the wine filtration. For wineries who prefer enclosed filter systems we offer lenticular housings for the filtration with depth filter lenticular modules. Read more about nour wine filtration solutions

![]()

BEER

FILTROX is well known in breweries across the world. From washable support sheets (DUROFIL) over plate and frame filters to fully enclosed lenticular modules systems and a full range of filter cartridges, we offer the complete range of filter media and media-carrying apparatus for beer filtration.

Are you growing your operations and consider using filtration? Our experts work with craft brewers as well as with regional and global players on an everyday basis.

DISTILLED SPIRITS

Spirits such as whisky, vodka or fruit liquors and other alcoholic solutions are very complex liquids which differ greatly depending on the raw material used, the alcoholic fermentation, the distilling method, the blending and maturing technique employed.

In the production of distilled products, great care is taken at each processing step. Production is regarded often more as an art than a science and is often a well-guarded secret. The FILTROX Group is proud to be a supplier of many of the world’s leading producers of fine spirits.

To produce a clear and stable end-product the spirits/alcoholic solutions are often cooled to sub-zero temperatures. Depending on the product, fining or processing additives are added. Activated carbon (AC) may also be introduced at this stage.

HARD SELTZER

Since the demand for low calorie drinks is growing, hard seltzer products have been successfully implemented by many beverage producers. Usually after fermentation, the beverage is visually hazy with a slight color. Get the product ready for flavor addition without too much time and effort.

Read more about Hard Seltzer filtration solutions

![]()

FRUIT JUICE

Fruit juice, mainly apple juice concentrate and berry juice processing have undergone substantial changes lately. The traditional juice clarification process (fining method) has been partially replaced with warm juice treatment such as ultra- and micro-filtration processes and in doing so processing- and filtration additives have been reduced. With our high performance series, we offer a range of filter media with high capacity and proven efficacy in holding back spores of the unwanted Alicyclobacillus spp.

SOFT DRINKS & SYRUPS

This group of drinks includes colas, various flavored cool-drinks and lemonades made with water or spring water, with added sugar or sweeteners and usually include additives such as flavoring, coloring, acids, thickeners, stabilizers and preservatives.

Usually, the fruit juice concentrate and the used sugar syrups have to be filtered. DE filtration is rarely applied and in most cases only a sheet or module filtration is carried out, using clarifying media. If the sugar quality is not very high, a decolorizing step with activated carbon has to be added.

Bottled water is usually filtered through a sterile cartridge prior to packaging.

OLIVE OIL

Olive oils always evolve negatively over time. Thus, a filtration is recommended in order to stabilise them and to obtain an organoleptically superior oil. In short, filtration avoids the negative contribution of the evolution of the impurities (anaerobic fermentation).

FOODSERVICE FRYING OIL FILTRATION

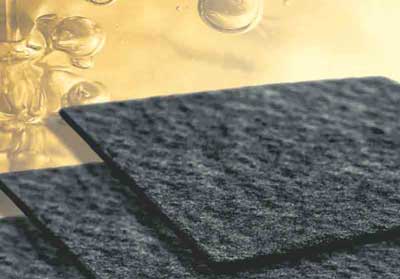

SuperSorb® Carbon Pads – An innovation in frying oil filtration and treatment. Developed for and with foodservice operators, specifically for the filtration and treatment of frying oil. A unique combination of activated carbon and specialty adsorbents, built into a depth of cellulose fibers, offer both a fine oil filtration and treatment by removing damaging

contaminants.