HARD SELTZER FILTRATION

Hard Seltzer – A Clear Solution

Background and Challenge of Hard Seltzer

The demand for low calorie drinks is constantly growing and hard seltzer products have been successfully implemented by many beverage producers. After fermentation of the sugar-solution, the hard seltzer base is visually hazy with a slight color and unwanted fermentation off-flavors.

Due to the different raw materials and challenging fermentation conditions, achieving the highest quality in the final seltzer product is a challenging task. Customers demand a clean, refreshing, and flavorful final product. The following chart shows a typical filtration and treatment process for a clean seltzer base which is key for highest final product quality. Variations might be considered depending on clarification method and desired final product quality.

Treatment with immobilized activated carbon

Activated carbon treatment works through the mechanism of adsorption, where the impurity adheres to the surface of the activated carbon. Treatment with immobilized activated carbon is much more efficient compared to loose carbon powder due to a forced contact of the impurities with the activated carbon. Therefore, shorter contact time can be applied and less carbon needs to be used.

STEP 1

Hard Seltzer base after fermentation

- Inital clarification step after fermentation in single or multi-step filtration

- Removal of any particels, yeasts and solids material to obtain a bright base

STEP 2

Bright base after filtration

- Activated carbon treatment to produce a colorless and sensory neutral base

- Removal of unwanted fermentation off-flavors and color adjustment

STEP 3

Filtered and treated base ready for flavor addition

- Final filtration step after flavor addition to guarantee highest product quality and safety

- Preservation of taste and aroma post packaging

| Product | Filter media | Application | |

| STEP 1 | FIBRAFIX® / FIBRADISC® | Filter sheets and modules | Fine filtration for hard seltzer after fermentation. Removes turbidity and delivers constant product quality. |

| STEP 2 | ACTIVASORB® / ACTIVADISC® | Filter sheets and modules | Treatment with immobilized activated carbon for color and taste adjustment. |

| STEP 3 | CLAROX® | Filter cartridges | Final filtration for process safety and best preservation of aroma and taste. |

See here an application example …

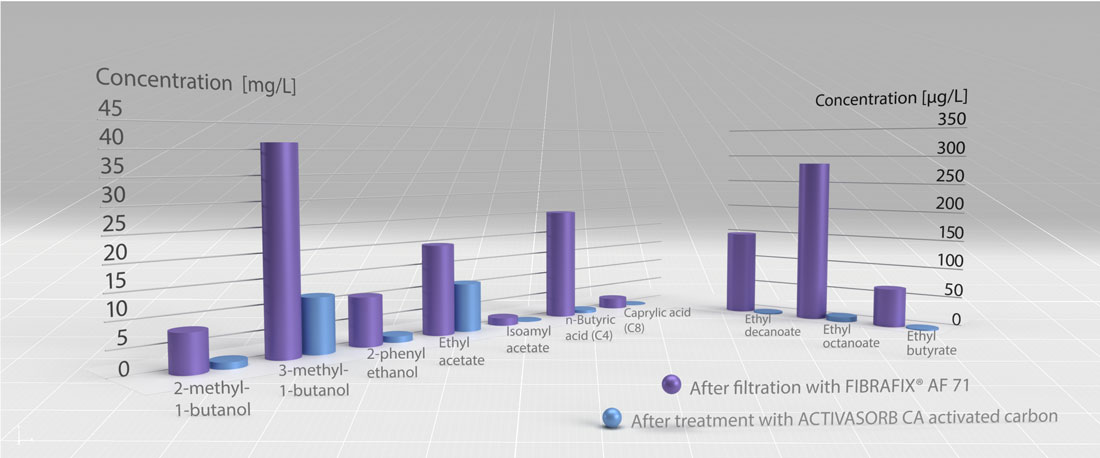

After fermentation of a glucose solution on a pilot plant scale, a two-stage filtration was carried out. In the first filtration step, FIBRAFIX® AF 71 sheets used for a clarification filtration removed all trub particles and yeast cells. The subsequent treatment with ACTIVASORB® activated carbon media, resulted in a decolorization of the solution and removal of undesirable fermentation aromas.

Aroma analysis by gas chromatography showed the effect of the immobilized activated carbon filtration on various fermentation by-products. A significant reduction of the initial concentration was determined for all analytes investigated. For many analytes, the concentration was below the limit of quantification of the used methods after the treatment with immobilized activated carbon, thus almost a 100% removal of those undesired aroma compounds could be achieved.

Easy handling and high efficiency

Depth filter media has been used for centuries and offers excellent filtration performance

and high filtration efficiency.

Highest product quality

Immobilized activated carbon filter sheets and modules are easy to

handle and highly effective in the removal of unwanted off-flavors

and color from your seltzer base.

Best aroma & taste prevention

Depth filtration technology securely removes any unwanted particles and

microorganisms that could negatively affect the final product quality.

Related Products

BROCHURES

FILTRATION KNOWLEDGE