WINE FILTRATION

About wine filtration

The removal of solid particles, microorganisms and other undesirable substances that could affect the sensory properties or visual appearance of the wine is crucial to meet customer expectations. The use of filtration in winemaking stems from the need to produce consistent and high quality wines. Depth filtration technologies have been used in the wine industry for centuries and play a fundamental role in removing unwanted particles, increasing stability, preventing microbiological spoilage and improving sensory quality.

OPTIMIZED SOLUTIONS FOR WINE FILTRATION

The following overview shows a typical filtration process for wine from initial clarification to sterile filtration. Depending on the type of wine, the style of winemaking and the desired wine quality, different options should be considered. The appropriate filter medium is selected depending on the type of wine and the desired degree of filtration. FIBRAFIX® AF depth filter media is a proven and well-tested filtration technology for all steps of wine filtration. The three-dimensional depth filter media ensures excellent retention of solid particles and unique filtration properties with cost-effective performance.

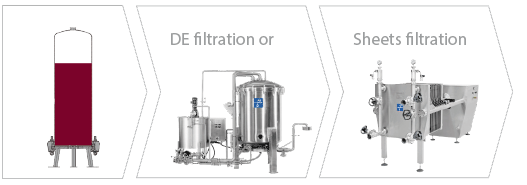

Coarse Filtration

The wine is cloudy but translucent.

- Initial clarification step after fermentation or stabilization

- Removal of larger particles like yeast cells, tartaric acid crystals or wine fining agents

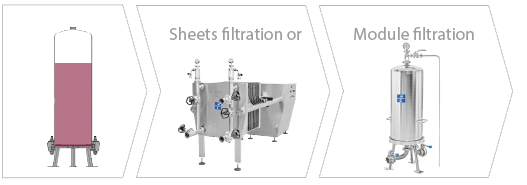

Fine Filtration

The wine is clear and bright. Stable wines are ready for bottling. Just before

bottling line a cartridge of 3 μm ABS is suggested for safety reasons. At this stage we consider yeasts and bacteria reduction only.

- Producing a bright wine by removing any remaining particles

- Prepare wine for final or sterile filtration

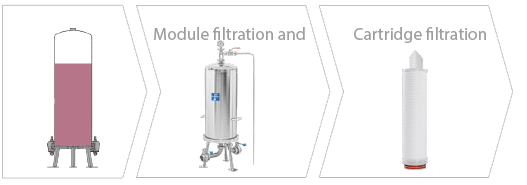

Sterile Filtration

The wine is clear, bright. Required by sweet or malic acid presence (no second fermentation concluded) wines. A final membrane cartridge 0.65 μm for red and 0.45 μm for white wines is strongly suggested before bottling line.

- Final filtration step to guarantee highest product quality and safety

- Securly removing wine spoilage organisms that can cause microbiological issues, off flavors or turbidity post bottling

Best Practices for the Wine filtration |

|

|

First rinse the filter media with clean water. At 1.5 times the recommended filtration flow rate at > 1.0 bar back pressure. Before filtration, it is recommended to taste the rinse water (so-called no paper aroma). |

Avoid pressure surges or flow fluctuations during filtration. Would you like to benefit from all depth filter effects such as surface, depth filtration and adsorption? Please respect the recommended flow rates. |

|

All filter media can be sterilized with hot water. Please refer to the respective product specification. |

After each regeneration of the membrane cartridges, an integrity test is recommended to check and ensure the integrity of the membranes. |

Easy handling and high efficiency

In the wine sector depth filter media have been used for centuries and offer excellent filtration performance and high filtration efficiency.

Maximum flexible

With a wide range of FIBRAFIX® AF grades available, any filtration needs from coarse to sterile can be met to find the right solution for your process.

Consistent quality

Depth filtration technology securely removes any unwanted particles and microorganisms that could negatively affect the final wine quality.

Filter sheets and filter module grades

(please note, all sheet grades are available in lenticular module and special formats too)

Filtration steps |

Description |

FIBRAFIX® sheet grade |

Retention rate µm |

| Coarse filtration | Removal of coarse particles and debris |

AF 09 |

10 – 30.0 |

|

AF 11 |

10 – 30.0 | ||

|

AF 17 |

8.0 – 20.0 | ||

| Fine filtration | Final filtration before sterile filtration or bottling, depending on wine type |

AF 71 (barrique wines) |

1.5 – 3.0 |

|

AF 101 (brilliant) |

0.6 – 1.5 | ||

| Sterile filtration | Final filtration before bottling or pre-filter before membrane cartridge (CLAROX® MP) |

AF 110 (germ reduction) |

0.5 – 0.5 |

|

AF 130 (red and white wines) |

0.4 – 0.6 | ||

|

AF 140 (white wines) |

0.2 – 0.4 | ||

| Treatment | Removal, reduction of unwanted aromas and flavors |

LIBRASORB® MX and TX |

refer to the technical data sheet |

FILTRATION KNOWLEDGE