Hemp Extracts and CBD-Oil

The Challenge

Producing pure and safe CBD-oil is the goal of every quality-conscious manufacturer of cannabis products. Raw hemp extracts contain high concentrations of cannabinoids, but also contaminants and impurities like plant particles, chlorophyll and debris as well as unwanted oils and waxes. Therefore certain contaminants should be removed:

Chlorophyll:

• bitter taste and highly unstable

• will cause degradation of cannabinoids

Waxes:

• very sticky components

• removal leads to smoother texture and consistency

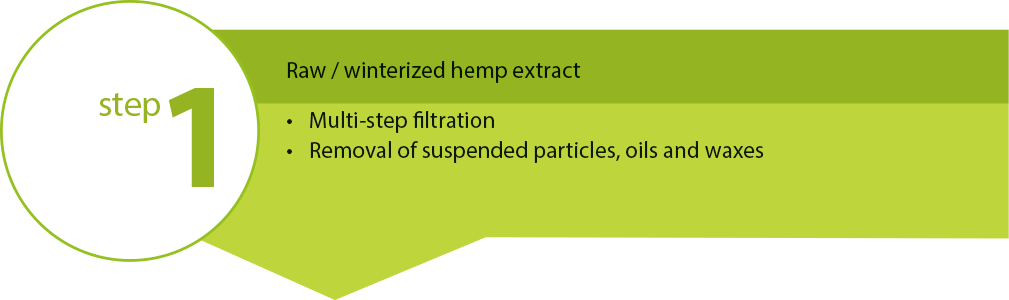

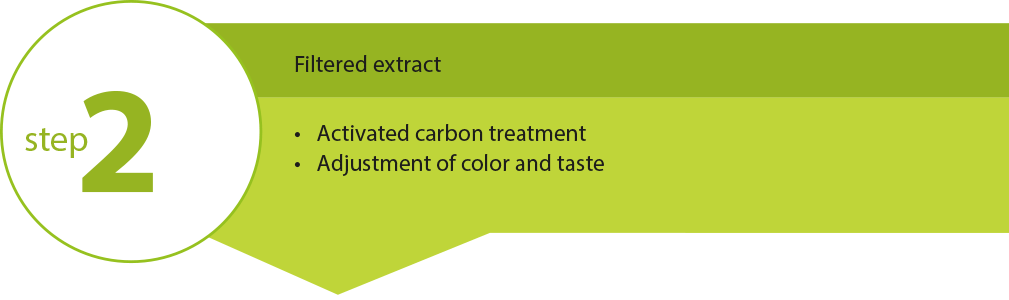

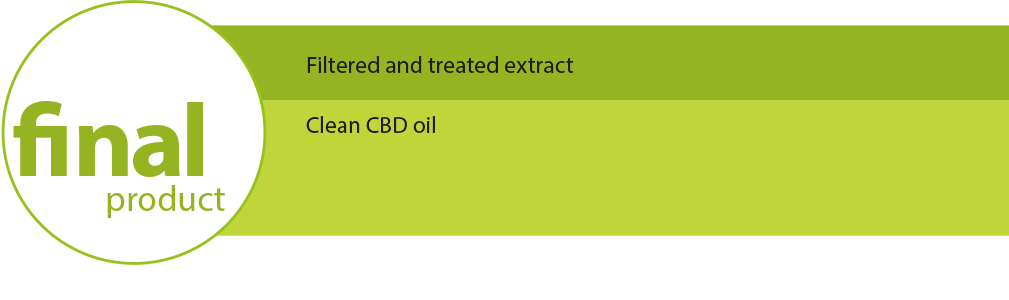

Filtration and purification steps of CBD- oil

In order to ensure product quality and safety for CBD-oil products, filtration is essential. The following chart shows a typical filtration process. Variations might be considered depending on extraction method and type of product as well as desired quality.

|

|

|

|

|

|

|

|

|

|

|

| Optimized solutions for filtration and purification |

step 1 |

PURAFIX® depth filter sheets are thick, cellulose based filter media, low in extractable ions, that capture contaminants within their matrix. The following table shows the best suited products for the different filtration steps. |

| Product | Description | Nominal retention rate | Best use |

| PURAFIX® CH 09 | coarse filter sheet | 30 – 10 μm | removal of particles and debris |

| PURAFIX® CH 31 | fine filter sheet | 12 – 5 μm | removal of fine particulate and waxes |

PURAFIX® sheets are engineered for and currently used in FDA approved pharmaceutical and biopharmaceutical applications.

step 2 |

ACTIVASORB® products are impregnated with activated carbon. They are used for the purification of CBD-oil, to remove chlorophyll and remediate color and taste. Activated carbon treatment works through the mechanism of adsorption, where the impurity adheres to the surface of the activated carbon. |

| Product | Description | Best use |

|---|---|---|

| ACTIVASORB® | treatment product with immmobilized activated carbon | chlorophyll removal, color and tast adjustment |

Treatment with immobilized activated carbon is much more efficient compared to loose carbon powder due to a forced contact of the impurities with the activated carbon. Therefore, shorter contact time can be applied and also less carbon needs to be used.

Easy handling and high efficiency

Immobilized activated carbon filter sheets are easy to handle and highly effective in the removal of

color and taste in hemp extracts and oils.

Flexible optimization

Various PURAFIX® grades are available, from sterile to coarse filtration. This enables you to find the right solution for your process.

Linearly scalable

Depth filtration technology is easily scalable due to its linearity. The filter material is identical from lab scale to production scale and offers solutions for any size of operation.

Related Products

Filter Media