MAMMALIAN CELLS & MAB’S

BACKGROUND AND CHALLENGE

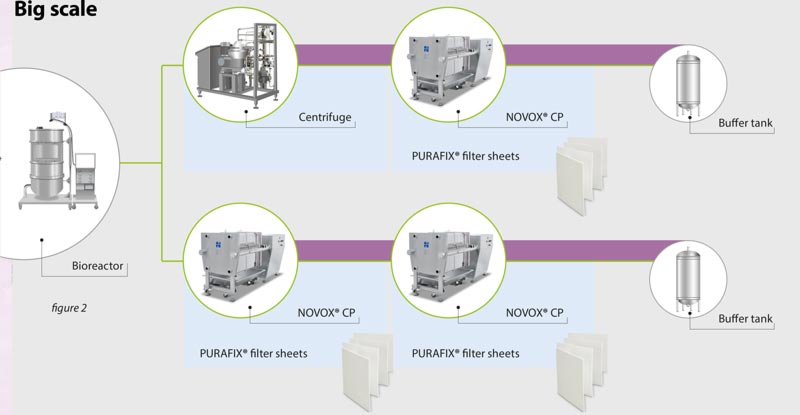

The ongoing optimization of mammalian cell lines and fermentation processes leads to higher cell densities/titers and higher monoclonal antibody ( mAb ) yields. Due to this optimization also the biomass increases, including cell debris and other impurities, which challenges the clarification/harvest step. The traditional filtration approach as well as the single-use approach are shown below.

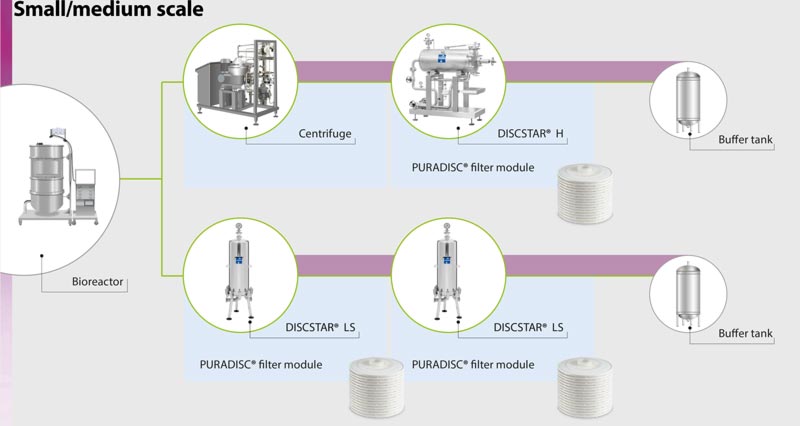

The typical clarification process for mammalian cells

and mAb involves a primary and a secondary clarification step. Centrifugation is the most common technology for large scales. Due to potentially high shear forces and the necessity of this step to remove submicron particles, depth filtration is a mandatory step before transferring the liquid into the downstream. The process combines low running costs with operating robustness.

Another option is the use of two depth filtration steps. A coarse filtration followed by a fine filtration. Both approaches need time, in some cases extra equipment and have high investment costs.

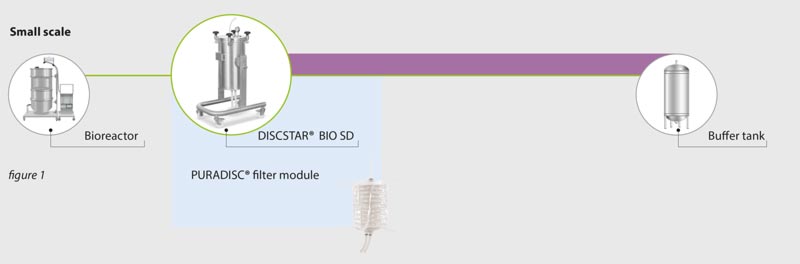

The single-use approach for mammalian cells clarification

The use of single-use equipment becomes more and more state of the art, especially for smaller production scale and manufacturing sites with frequently changing productions. The FILTROX approach is the combination of depth filtration and alluvial filtration.

THIS TYPE OF DEPTH FILTRATION CAN REMOVE THE CENTRIFUGATION STEP AND REDUCE THE CLARIFICATION TO ONLY ONE STEP.

For alluvial filtration it is necessary to add filter aid, like diatomaceous earth (DE), to build a filter cake on top of the depth filter sheets. The DE is added to the fermentation broth, mixed for a couple of minutes and then pumped into the depth filtration unit PURADISC® SU. For upscaling, the necessary space for the filter cake needs to be calculated. In comparison, for the standard calculation the filter area is the parameter of interest. Cells and cell debris remain in the filter cake and/or in the filter sheet. However, charged particles are being removed due to the electrokinetical potential of the filter sheet.

THIS TECHNOLOGY COMBINES THE ADVANTAGES OF ALLUVIAL AND DEPTH FILTRATION.

We offer both, depth filtration solutions for the traditional and the single-use approach. These flexible technologies fit all needs and applications for the purification of high value liquids e. g. mAb and mammalian cells.

Single-use approach of clarification

Small to big scale with the SU system

| Product | Description | Application | Best use |

|

PURACAP® SU capsules |

2″ for lab trials, 5″ for batches up to 10 L, 10″ for batches up to 25 L |

Adaptable to user needs | Removal of cells and cell debris |

| PURADISC® SU modules | 12M, 12S, 12D and 16D depth filter modules in a bag with space to build a filter cake | Adaptable to user needs | Removal of cells and cell debris in pilot and production scale |

| Diatomaceous earth | 30 g to 15 kg CELPURE® pharma grade DE | Pharma grade filter aid | Avoids clogging of the filter, increases the filterability up to 4 times |

| DISCSTAR® SU | Stainless steel support housing for PURADISC® SU modules | From pilot scale to fully automated production scale | Support housing for protection of the filter modules |

Save one Process Step

Using alluvial filtration for the clarification step eliminates the need for the two-step approach of centrifugation followed by depth filtration.

Flexible Optimization

Different types of diatomaceous earth and PURAFIX® filter sheets can be combined, and thus enable you to optimize the respective production process.

Linearly Scalable

The FILTROX SU system is linearly scalable from process development up to production scale. The transfer from method development stage to large-scale processes can be easily achieved due to linear scalability.

Traditional approach of clarification

| Product | Description | Application | Best use |

| PURAFIX® filter sheets | Low ion and low pyrogen containing filter sheets | Sizes between 6 cm round and 1.2 × 2.4 m possible |

Clarification of high value liquids |

| PURADISC® modules | Filter modules with PURAFIX® sheets in 12″ and 16″ | DOE and DOR adapter | Clarification of high value liquids |

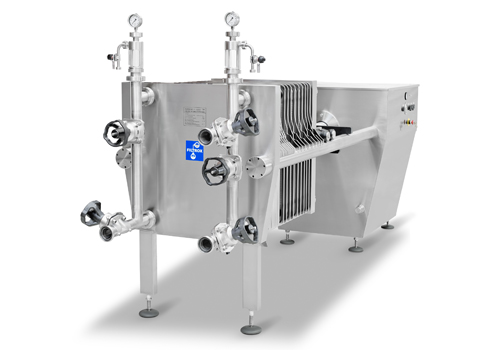

| NOVOX®-CP | CIP/SIPable sheet filter in different sizes | No drip loss, closed system | Clarification of high value liquids |

| DISCSTAR® LS | Housing for lenticular filter modules | For 1 to 4 modules | Depth filtration of turbid solutions |

| DISCSTAR® H | Horizontal housing for lenticular filter modules | For 2 to 4 modules | Economic depth filtration of turbid solutions |

PURAFIX® filter sheets and modules, NOVOX®-CP and DISCSTAR® filter systems are designed to give the best performance for highly sensitive filtration tasks.

Large Filter Area on a small Footprint

Depth filter modules and filter sheets enable large filter areas to be handled easily thanks to

their compact design.

Flexible Optimization

Various PURAFIX® grades are available, from coarse to sterile filtration. This enables you to

find the right solution for your process.

Linearly Scalable

Depth filtration technology is easily scalable due to its linearity. The filter material is identical

from lab scale to production scale. FILTROX offers depth filtration systems for any size of

operation.

Related Products