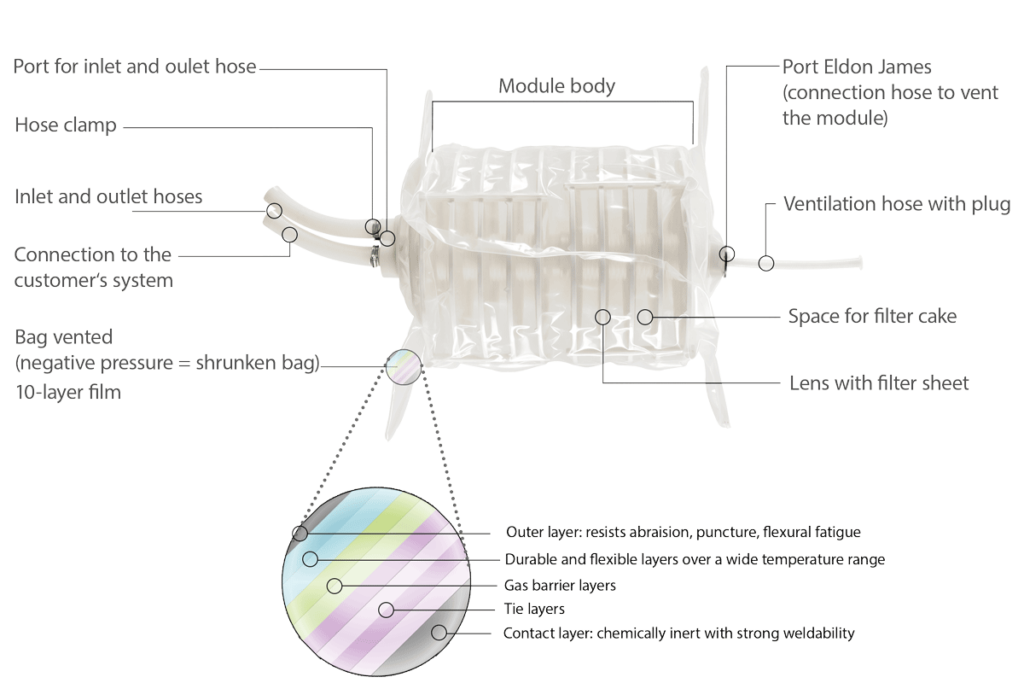

PURADISC® SU – Single-use depth filtration technology

PURADISC® SU is a depth filter using the advantages of the alluvial filtration technology (specifically cake or precoat) in a disposable format. The filtration system removes particles (e. g. cells, bacteria, yeast), impurities and other turbid matter. Typical applications are for example, CHO cell removal, bacterial removal and many more. Its closed-system design ensures no environmental contact, making it particularly suitable for cell and gene therapy, biologics, and pharmaceutical applications. The transfer from the method development stage into large-scale processes can be easily achieved due to linear scalability.

The new PURADISC® SU is designed to bring alluvial filtration to the next level, offering greater flexibility, efficiency, and process safety. With single-use technology, companies can reduce downtime, eliminate cleaning and cleaning validation requirements, and accelerate time to market—all while minimizing contamination risks. Therefore, this method is the ideal choice for contract manufacturers (CMO) and other operations with a high frequency of product range.

Fully gamma-sterilized and ready to use, PURADISC® SU meets the highest regulatory standards in materials, production, and documentation. Validated packaging and transport solutions ensure the preservation of streility. Adaptions for the use in a GMP area are possible on request.

In addition, the PURADISC® SU system is completely disposable. In other words, all material that comes in contact with the product is meant for single-use and can be disposed of after the filtration is compleated.

Experience enhanced process efficiency, faster turnaround times, and simplified operations with PURADISC® SU — your solution for next-generation biopharmaceutical manufacturing.

Application examples

- Gene therapy

- Biologics

- Pharmaceutical applications

- CHO cell removal

- Bacteria (e. g. E.coli) removal

- Cell debris removal

- Insect cells removal

- Plasmid DNA purification

- Yeast removal

- HPC removal in one step / e. g. up to 30–40% HPC from the fermentation broth

First in the live science industry to introduce body feed filtration for Midstream

(Comment from a famous US biotech company)

applications in a single-use format.

“It’s like building your depth filter.”

For continuous manufacturing, DISCSTAR® SU SKID enables seamless integration into advanced bioprocessing workflows. As the only alluvial filtration system from a leading manufacturer, it delivers significantly higher filter capacity within the same filtration area, setting a new industry standard.

Single-Use Application

– No cleaning

– No cleaning validation

– Less downtime

– No CIP, SIP or WFI preparation

– Fast product changes, setup, adaption

– No cross-contamination

– Very low dead volume

– Gamma sterilized for immediate use

Technology

– Established technology

– Ideally suited for gene and cell therapy applications

– Extended filtration capacity using alluvial filtration (especially for high-density proteins)

– Completely closed, drip-free system

– High flexibility in filter configuration (filter sheet grades, connections, …)

– Compact dimensions

– No need for pH changes nor flocculants

Scalability

– Linear scalability through tools in different size ranges

– From laboratory to production scale

-Determining the ideal filter grade from as little as 20 mL

Sustainability

– No cleaning = reduced water and energy consumption

– Up to 92% less plastic than comparable systems for the same filter area

– Good recyclability of materials (plastics)

– Energy-yielding, unproblematic combustion possible

SU Filter modules and capsules

PURACAP® SU 2″ Capsule

|

Batch range [liter] | Up to 2 L |

| Cake volume [liter] | 0.06 | |

| Filter area m² | 0.002 | |

| Application | Proof of technology, evaluation of DE grade |

PURACAP® SU 5″ Capsule

|

Batch range [liter] | Up to 10 L |

| Cake volume [liter] | 0.38 | |

| Filter area m² | 0.0127 | |

| Application | Evaluation of 2″ results, small pilot scale |

PURACAP® SU 10″ Capsule

|

Batch range [liter] | Up to 20 L |

| Cake volume [liter] | 1.5 | |

| Filter area m² | 0.05 | |

| Application | For customers using fermenter farms up to 30 L |

PURADISC® SU 12″ Short module – 12M

|

Batch range [liter] | Up to 100 L |

| Cake volume [liter] | 3.5 | |

| Filter area m² | 0.33 (up to 0.675) | |

| Application | Pilot scale |

PURADISC® SU 12″ Single module – 12S

|

Batch range [liter] | Up to 200 L |

| Cake volume [liter] | 9.9 | |

| Filter area m² | 0.55 (up to 1.8) | |

| Application | Bio process scale |

PURADISC® SU 12″ Double module – 12D

|

Batch range [liter] | Up to 500 L |

| Cake volume [liter] | 19.8 | |

| Filter area m² | 1.1 (up to 3.6) | |

| Application | Bio process scale |

PURADISC® 16″ Double module – 16D

|

Batch range [liter] | Up to 1000 L |

| Cake volume [liter] | 40.7 | |

| Filter area m² | 2.26 (up to 7.2) | |

| Application | Bio process scale |

Support systems

For the use of PURADISC® SU single-use modules, special stainless steel housings are necessary.

DISCSTAR® SU 12″ short support system

|

Max. operating pressure | 0 – 3 bar |

| Capacity | 13.6 L (empty housing) | |

| Weight | 35 kg | |

| Material | Stainless steel AISI 304 |

DISCSTAR® SU 12″ double support system

|

Max. operating pressure | 0 – 3 bar |

| Capacity | 51 L (empty housing) | |

| No. of modules | 1 × 12″ (double module) | |

| Material | Stainless steel AISI 304 | |

| Also available as single version for single modules. | ||

DISCSTAR® SU 16″

|

Max. operating pressure | 0 – 3 bar |

| Capacity | 90 L (empty housing) | |

| No. of modules | 2 × 16″ | |

| Material | Stainless steel AISI 304 |