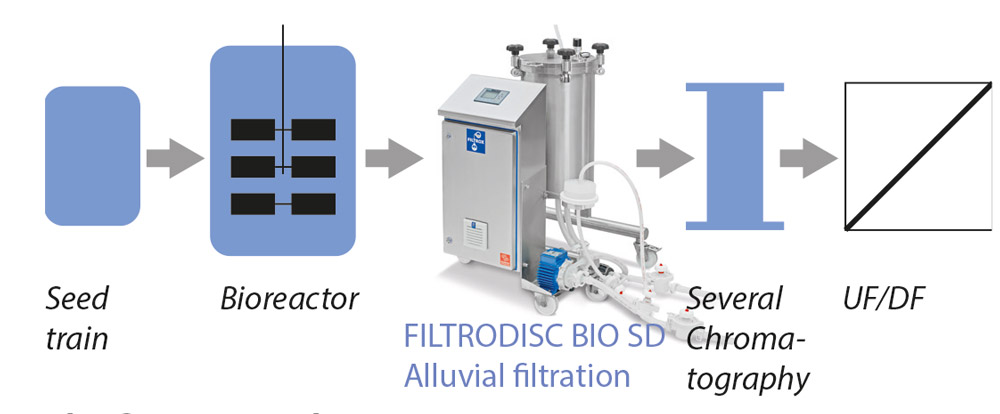

An Economical Solution for Midstream Clarification

Introduction

Continuous process optimization is a key factor in the biotech industry. With higher particle loads (>108 cells/ml), standard technologies for cell removal (midstream processing) – e.g. centrifugation, separation, membrane- and depth filtration – find their limits.

To increase efficiency and making the midstream process more economical alluvial filtration is the state-of-the-art solution. Alluvial filtration is a type of depth filtration and a well-established, econo-mical method in pharmaceutical industries (e.g. plasma fractionation). Instead of using an immobilized depth filter medium, filter aid (e.g. diatomaceous earth, perlite) is used to constantly build a filter cake during filtration. The filter cake with its resistance acts then as the actual filter medium. Alluvial filtration, therefore, leads to a higher filter capacity – especially with compressible particles, e.g. microbial or mammalian cells. This technology leads to a maximum product yield and highest economic efficiency and is linear scalable from lab to production scale.