One of the most important tools in your oil management tool box is the oil filter or treatment. For over fifty years, we have known some keys to properly managing oil are:

- Design, construction & maintenance of equipment

- Proper operation of equipment

- Proper cleaning of equipment

- Minimize exposure to UV

- Keep salt & metals away from oil

- Filter regularly

When it comes time to select a filter or treatment system for your oil, the first consideration is that the product has significant benefits to your operation. The benefits could be improved food quality, longer oil life, or reduced frying oil usage. The operator should also make sure that the product that is selected not be absorbed or remain in the oil. There are even some who feel that the filter or treatment system should never even be put into the oil believing that free form powders cannot be completely removed from the oil during the filtering process.

Why such a constraint?

If a product is put into the frying oil and allowed to stay in the oil, there is a potential for that product to get into the food rendering it adulterated. Unless of course the fryer operator is going to declare that additive as part of the food. There have been documented cases in which laboratory testing of products fried in oil containing free form powders developed a gritty taste that was attributed to the powder. A later test of the batter on the product isolated the oil treatment product from the product coating. The more insidious oil treatment is a liquid product that some companies have actually said “Add to the oil and keep frying.” That could and has been done, but were the additives declared? Or, more to the point, if it was your operation, do you want to declare the additive?

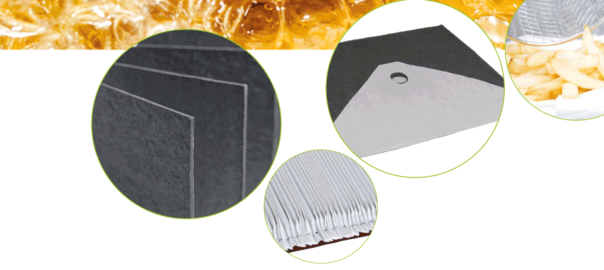

The best filtration solutions

The best oil filter or treatment media are ones that are incorporated into pads or papers: pads or papers that have been rigorously tested and found to be stable. By stable, we mean that there is no leaching of the components into oil or water when subjected to testing. It also means that the product withstands high temperatures and variable flow rates and maintains its integrity. The laboratory data on stability must also be validated during actual use in frying systems. It does no good to have great laboratory data if the product does not stand up to “real world” applications. And guess what? Our SuperSorb® products demonstrate all of the necessary characteristics in addition to being a great oil treatment method that will benefit your frying operations in many different ways.

We make a filter to fit most major fryer filter machines on the market. Start improving the life of your oil now and have more consistent food quality all while saving money.