SuperSorb® CARBONPAD IMPROVES FAST FOOD FRYING OPERATION COMPARED TO ADSORBENT POWDER and SYNTHETIC FILTER SHEET AND TO IMPREGNATED PAPER

A multinational fast food concept made a management decision to re-evaluate frying operations. The improvement plan included examining oil treatment/filtration technologies, evaluating in-store oil testing methodologies, a commitment to cleaning and a greater emphasis on preventive maintenance. Ultimately, management wanted to increase the efficiency of frying operations, improve food quality and establish more quantitative, reproducible methods for monitoring frying oil quality.

This application note addresses the results from the first of those objectives; evaluating efficacy of different filter media products for both the extension of useful frying oil life and for enhanced food product quality. The concept utilizes three fryers in each store. Prior to initiating the study, each fryer was cleaned utilizing the company’s new and improved boil out procedure. The food mix in each fryer varied. One fryer was used to fry starches (fries & potato products) only. The second fryer was used for fries and coated non-meat items, and the last fryer was dedicated to chicken tenders.

TESTING & EVALUATION

Management decided to evaluate two filtration/treatment technologies, and compare those results to the current filter product (baseline); (1) SuperSorb® CarbonPad, and an (2) other filter pad with an activated silica-based loose form adsorbent powder were chosen for evaluation. Baseline consisted of a diatomaceous earth (DE) impregnated paper.

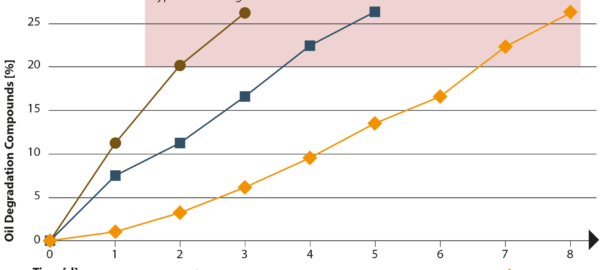

Each trial was initiated using fresh oil and continued until the oil was deemed unacceptable using an oil test meter, and the 3M test strip. Discard was 24% Total Polar Materials (TPM) and an FFA level of 6.0 – 7.0%, respectively. Company personnel also monitored the sensory properties of the different food products to establish a direct relationship between the food and degrading oil quality. The volume of food that was fried each day was recorded, and the oil filtered at the end of each day’s production. The oil was tested daily after filtering, but before the fryer was topped off. Results were recorded. In addition, the study monitored procedures that would affect operating efficiencies such as filtering time for each variable, operating costs for each filtration/treatment technology and oil usage. The study also evaluated employee acceptance of the different filtration/treatment technologies.

Test Objective

Determine which filter medium performs the best at slowing down frying oil degradation, thus extending useful life, and improving product quality.

Compare the following types of filtering methods against the current practice: DE Impregnated paper sheet is the baseline.

• Phase 1: other filter pad with an activated silica-based loose form adsorbent powder

• Phase 2: FILTROX-Filtercorp – SuperSorb® Carbon Pad.

Test Protocol

All fry pots boiled out at the beginning of each phase of the test.

Each fry pot is evaluated stand alone – no oil rotation.

Oil Sample Collection Protocol:

- Collect samples from pots 1 – 3 after filtering daily in the morning and afternoon.

- Collect samples when each fry pot is at 300 °F / 350 °F (149 °C / 176 °C).

- Collect samples from fresh oil while still in container.

Chemical Evaluation:

- Technical Laboratory Measurement

- Percent of FFA (Free Fatty Acids)

- Color by Lovibond

In Restaurant Measurement:

- Percent of TPM (Total Polar Materials) Discard Target – 24%.

- Percent of TPM via EBRO tool pre/post filtering.

- Free fatty acids via 3M Oil Quality Test Strips.

Success Criteria

- Extended Useful Fry Life over current &/or comparable methods.

- Reduction in Frying Oil Usage over current &/or comparable methods.

- Time required to filter over current &/or comparable method remains the same or is improved.

- Actual cost reduction.

RESULTS

The three trials were carried out over a period of approximately six weeks. This included allocating time before each trial started to ensure that restaurant staff were properly trained on use and handling of the different filtration/treatment technologies. The studies found that the SuperSorb® technology performed best. The oil treated with this system lasted an average of ten (10) days, whereas, the other filter pad with activated loose form powder lasted nine (9) days and the baseline – DE impregnated paper only five (5) days.

In addition, the SuperSorb® technology demonstrated other benefits. These included;

1. More rapid filtering time – only 15 minutes for all three fryers; 30 minutes less than the other filter pad with powder

2. There is no powder used with SuperSorb® and, hence, no handling or safety issues

3. Filtering is more effective – 0.5µm (micron) for the SuperSorb® technology versus 10µm for the other products

4. Enhanced product quality

5. Longer useable oil life

6. Lower daily cost than the other filter pad with adsorbent powder (over $1.00 per day less), and competitive with the DE impregnated paper (2 sheets used daily)

And, what may be most important to restaurant operators and their employees was an observation by the company’s team members that “Filtering is much faster and easier.” Finally, it is a fact of life that any technology that restaurant employees feel is easier and faster to use will, in fact, increase the chances that it is not only used, but will be used properly.