One of the challenges for foodservice and restaurant operators is determining when to discard frying oil. Throwing oil away too soon can cost the operator significant money in the long run. But using the cooking oil for too long can also impact your business negatively. The latter is much worse. As food that is fried in overused oil is of poor quality and very likely be rejected by the consumer. For a business that relies on repeat sales, this is not a good thing. That customer who purchased excessively greasy French fries or the burnt-looking fried chicken may never come to your restaurant again.

How does a restaurant operator determine when to dispose of their oil? At the third International Symposium on Deep-Fat Frying held in Hagen, Germany in 2000, the first recommendation made by attendees was the following:

The sensory parameter of food is prime quality index.

This is why people order fried food: it tastes and smells good and has a rich texture and mouthfeel.

To ensure that restaurant operators properly manage their oil, which includes determining when the oil should be discarded, it is imperative that the operators conduct the necessary evaluations. This is something that should be done by restaurant management, be it researchers for the large chains or store managers in smaller operations. This will ensure that management sets a clear guideline for when fry oil is past its prime.

There is no “one size fits all” answer to the question of when to discard used oil. To determine the ideal life of oil in your situation, you can conduct a simple experiment. Fry food until it is determined by management that the oil condition is no longer acceptable, making note of the amount of food produced. These frying studies should mirror actual restaurant practices and can even be conducted in real-time in a working restaurant. This observation process will allow the management to establish how long they can fry food before changing the oil.

These frying studies also provide operators with chance to evaluate different test systems aimed at providing the company with a true endpoint indicator. The test that is selected, whether it is a test strip, color comparator or a meter, should be run throughout the frying process. Then compare test results with sensory evaluation (fried food) to determine a measurable endpoint for discarding oil.

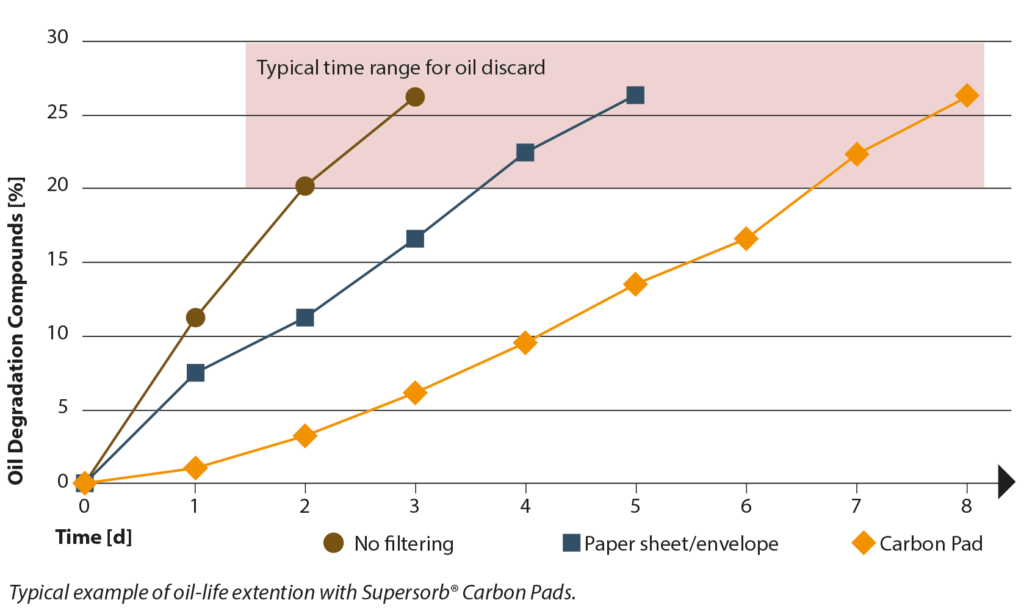

To extend oil life, saving money and keeping customers happy through consistent, high-quality food, consider switching to SuperSorb® Carbon Pads. SuperSorb® is proven to maintain oil life in the optimum range for longer versus other filters. Contact us today for a free sample and see the difference SuperSorb® can make for your oil life.