Frying is a popular method of cooking because it is quick, easy and usually results in delicious food.

During the frying process cooking oil is being exposed to heat and all kinds of contaminants (breading, batter, crumbs, marinades, ice particles from frozen food etc.) reducing its lifetime. To extend frying oil service life filtration is the most important step. It helps to control consistency of food and keeps operational costs down.

These are the common methods applied to frying oil.

Passive Filtration

Surface filtration / Passive filtration removes particulate from the oil through sieving. This is the method commonly referred to simply as “filtration”. Examples of passive systems are filter paper, bag filters and steel screens (mechanical removal of solids). This is anything from 2 mm to 4 mm screens down to typically 50 microns. These systems remove only the insoluble particulates of certain sizes.

Depth Filtration

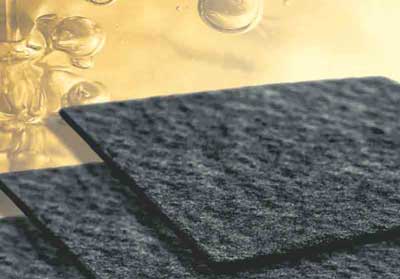

Depth filters consist of a relatively thick layer of porous materials containing irregular and tortuous channels. Particles are entrapped within this matrix. Depth filters have greater porosity than passive filters and are not “blinded” (reducing or shutting off pores, thereby shutting off flow through the filter) as easily as passive filters. The increased depth of the filter media allows multiple stages of filtration.

- arger solids are held on the surface of the pad.

- Smaller solids are trapped within the structure. The structure has a very high number of internal pores, it holds a high degree of solids.

- The internal structure gets thighter the further you travel through the pad ensuring even the finest solids are trapeed.

Active Filtration or Treatment

These filters include active materials such as adsorbent powders and activated carbon. Besides the before described surface and depth filtration. Filters with active powders (e. g. filter pads) remove and reduce metallic ions, soaps, color, odor, off flavors and even finer particulates suspended in the oil. The removal of these contaminants, help to extend the service-life of frying oil.

.

Efficient and Effective Combinations

The combination of depth and active filtration are the most efficient frying oil filtration media. They combine a fine filtration with treatment of the oil and do not only remove small particles, but also suspended contaminants. The combination of depth filtration and treatment results in the highest frying oil service-life and costs savings.

Important Note

For successful frying-oil-management, it is important to filter regularly. Filter frying oil twice a day should be the minimum to succeed in slowing down the oil-degradation process.

If you want to learn more about this and other frying oil technical topics, please contact FILTROX or find out more on our frying oil filtration page