Extending the frying oil shelf life whilst maintaining product food safety and quality is one of the goals of food service operators. Filtering the frying oil regularly is by far the most important recommendation to achieve it.

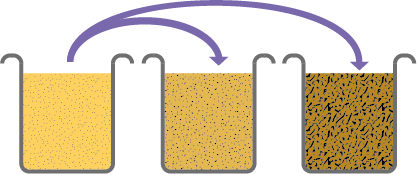

Besides filtering, there are 2 other procedures restaurants follow to try to extend oil life, named frying oil cascading (rotation) or “cradle to grave”.

The oil degrades at different rates in the fryers vats when frying different types of food. When operators use cascading, oil is moved from a Vat with lower debris, lighter oil color (less “hostile” frying oil environment) to Vats with higher debris and darker oil color (more aggressive circumstances).

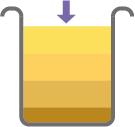

From experience, the frying oil life is maintained better when the “cradle to grave” operation is followed. There are some technical explanations that could support the preference for the “cradle to grave” approach.

Below are the advantages of it:

- No risk of frying oil contaminants being transferred from one frying vat to another.

- Less risk of allergens and off flavors cross contamination among products.

- No work involved in transferring the fryer oil from one vat to another.

- Easier to control frying oil service shelf life via frying oil quality parameters.

By working with the cradle to grave practice, the frying oil is allowed to run its normal degradation course and be discarded when the end point frying oil quality parameter is reached, thus maintaining a longer fry-life.

Therefore, it is always a good practice to maintain cradle to grave approach in restaurant fryer operations to obtain longer oil fry-life and avoid product food safety and quality issues.