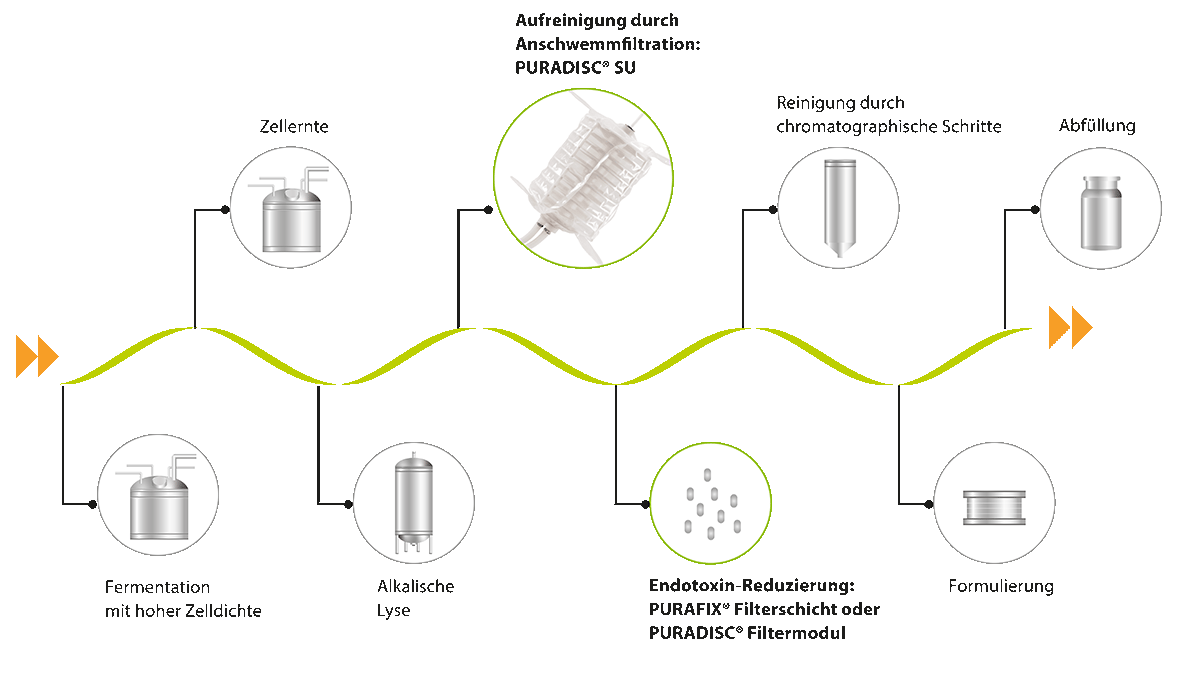

In this Application Note, the optimization of the filtration process of a mAb-contained CHO cell culture is shown in detail. So far, the suspension is filtered in three steps, before a sterile filtration using a 0.2 μm membrane is applicable. To ensure the sterile filtration step, a flocculant has to be added prior to each filtration. In order to reduce the number of process steps in the cell harvest process, filtration tests with FILTROX depth filter sheets are performed in the laboratory scale.

The aim is to determine the most suitable filter aid and its ideal quantity for the cell culture. And, in addition, to achieve turbidity values below 30 NTU to ensure subsequent sterile filtration.