PURADISC® SU – Next-Generation Single-Use Filter Modules for Alluvial Filtration.

Innovative. Efficient. Scalable.

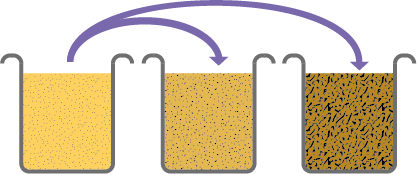

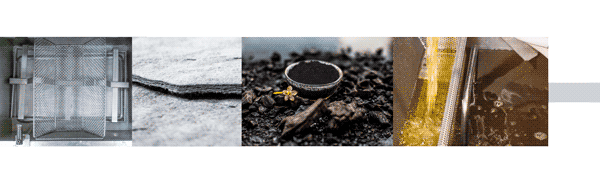

The new PURADISC® SU is designed to bring alluvial filtration to the next level, offering greater flexibility, efficiency, and process safety. With single-use technology, companies can reduce downtime, eliminate cleaning and cleaning validation requirements, and accelerate time to market – all while minimizing contamination risks.

Fully gamma-sterilized and ready to use, PURADISC® SU meets the highest regulatory standards in materials, production, and documentation. Its closed-system design ensures no environmental contact, making it particularly suitable for cell and gene therapy, biologics, and pharmaceutical applications. The time-consuming cleaning validation is no longer necessary when using the PURADISC® SU, as it is a closed and drip-free system.

FIND OUT MORE ⇒