In the highly competitive QSR-Industry, maintaining high-quality food standards while optimizing operational efficiency is crucial. A multinational fast food concept recently re-evaluated its frying operations to improve efficiency, food quality, and establish better methods for maintaining frying oil quality. A key part of this initiative involved evaluating different oil filtration technologies. The results revealed significant advantages of using the SuperSorb® CarbonPad over traditional methods.

Recently our FILTROX Team conducted a field test with a major QSR operator. Read here about the challenges we faced, the objectives, and finally about the resulting operatinal benefits and time savings.

The Challenge

The fast food chain aimed to enhance its frying operations by:

- Extending the service life of frying oil

- Improving food quality

- Avoiding filter media replacement because of blinding

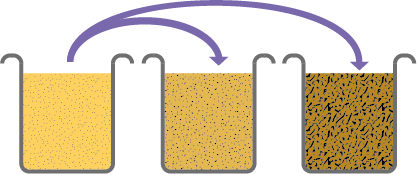

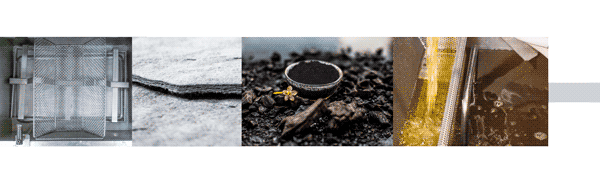

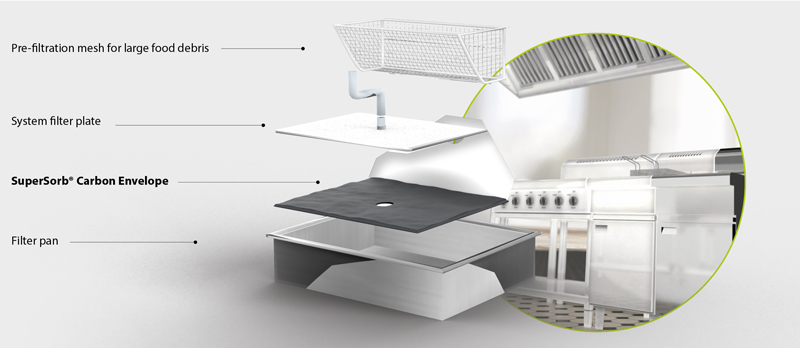

To achieve these goals, the company compared its current filtration product, a filter paper with an activated silica-based loose filter powderagainst the SuperSorb® Carbon Pad.

The Protocol and Objectives

The study was designed to determine which filtration medium best slows down frying oil degradation, thus extending its service life and improving product quality. The test protocol included:

- Cleaning each fryer using the company’s new boil-out procedure

- Evaluating fryers individually without oil rotation

- Daily oil sampling and testing Total Polar Materials (TPM)

- Monitoring sensory properties of food products

- Assessing filtering time, operating costs, and employee acceptance of each filtration method

Success Criteria

The success of each filtration method was measured by:

- Extended useful fry-oil life over current methods

- Reduced frying oil usage

- Filtering time efficiency

- Actual cost reduction

RESULTS

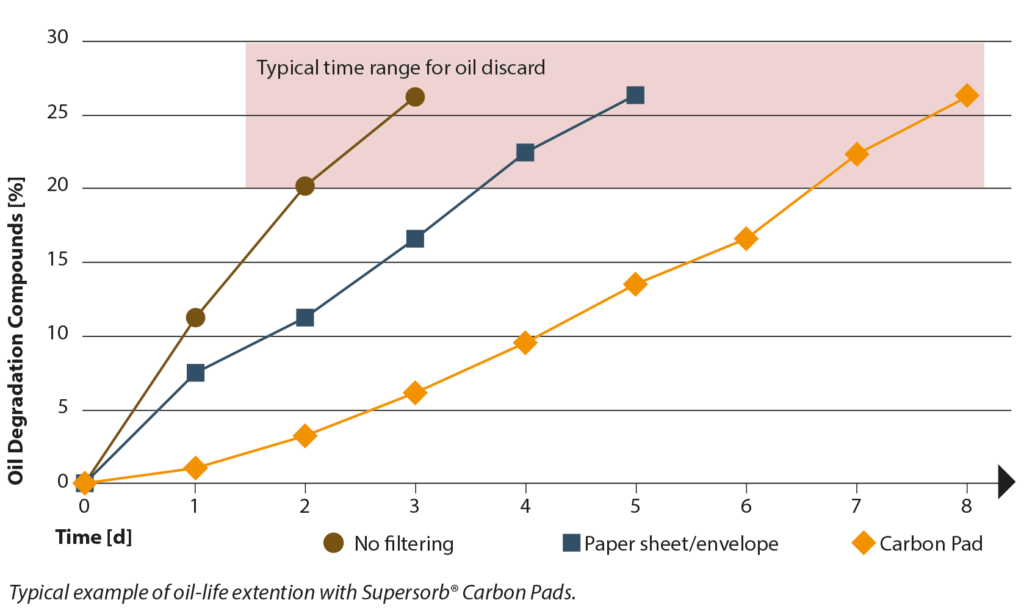

Over a four-week period, the study revealed that the SuperSorb® CarbonPad significantly outperformed the other filtration methods. Key findings include:

Extended Oil Life

- SuperSorb® Carbon Pad: Average of 7 days

- Filter Paper + Activated Silica-Based Powder: Average of 4 days

Faster Filtering Time

SuperSorb® required only 15 minutes for all three fryers, 30 minutes less than the other filter pad with powder.

Safety and Handling

SuperSorb® uses no powder, eliminating handling and safety issues.

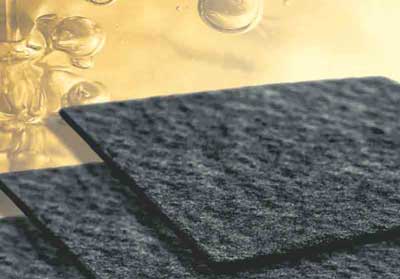

Effective Filtration

SuperSorb® with its embedded adsorbents, such as activated carbon, removes other chemical frying oil contaminants, filters down to 0.5 microns, compared to 10 microns for other filter pads.

Enhanced Product Quality

Improved food quality was consistently observed with SuperSorb®-filtered oil.

Cost Efficiency

SuperSorb® had a lower daily cost, compared to the filter paper with powder. Since the filter paper and powder combination blinded during they day, they had to replace paper and powder more than once a day. Only one SuperSorb® Carbon Pad was needed for the same amount of frying, saving fiter media costs and reduced labor costs.

Employee and Operational Benefits

One of the most significant advantages noted was the ease and speed of using the SuperSorb® Carbon Pad. Employees found the filtration and frying oil filter pad placement faster and easier, increasing the likelihood of proper and consistent use. This user-friendliness is crucial in a fast-paced restaurant environment, where efficient operations are essential.

Conclusion

The SuperSorb® CarbonPad has proven to be a superior filtration technology for fast food frying operations. Its ability to extend oil life, improve food quality, reduce costs, and simplify the filtration process makes it an invaluable tool for fast food restaurants aiming to enhance their frying operations. By adopting SuperSorb®, QSR operators can achieve better operational efficiency and deliver higher quality products to their customers.

Contact Us Today! See the difference for yourself with a free sample of SuperSorb® Carbon Pads. Experience firsthand the superior filtration and oil quality improvement that our pads offer.