FRYING OIL FILTRATION

SuperSorb® – An innovation in frying oil filtration and treatment

Developed for and with foodservice operators

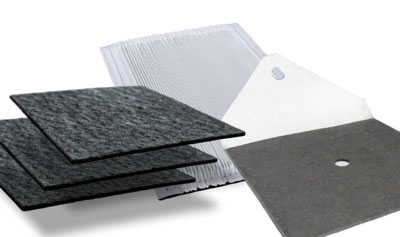

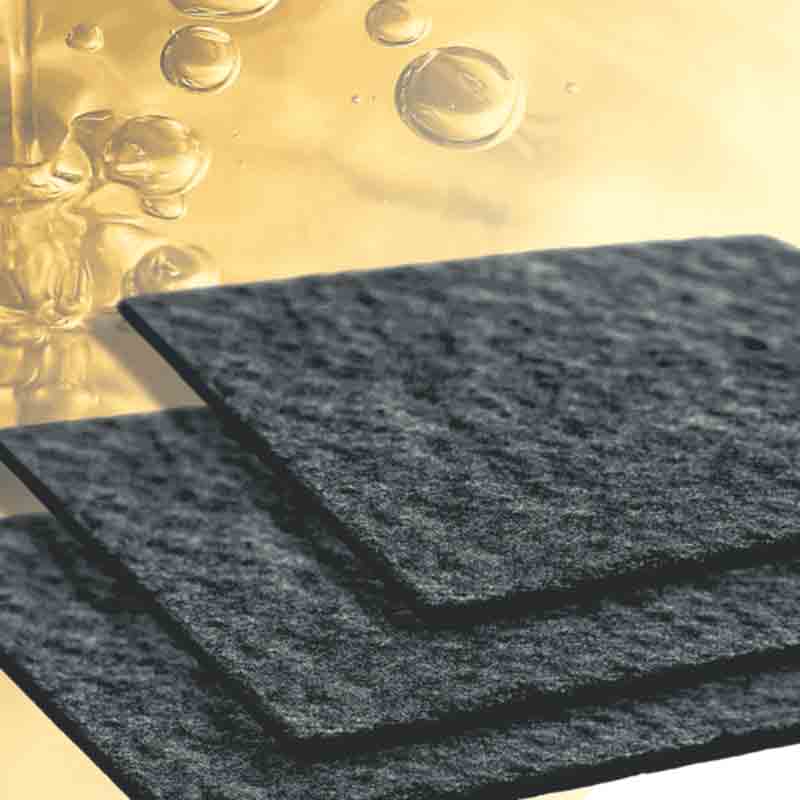

We developed Carbon Pads and Carbon Envelopes with and for foodservice operators, specifically for the filtration and treatment of frying oil. A unique combination of activated carbon and specialty adsorbents, built into a depth of cellulose fibres, offer both a fine oil filtration and treatment by removing damaging contaminants. Our Carbon Pads are easy-to-use and environmental friendly.

Faster daily oil filtration

No need for „polishing“ as the oil only needs one pass through the filter. After that, the frying oil is cleaner after filtration and therefore lasts longer. In short, you use less oil, offer consistent food quality, save labour costs and have an easier and safer operation.

How the Carbon Pads work

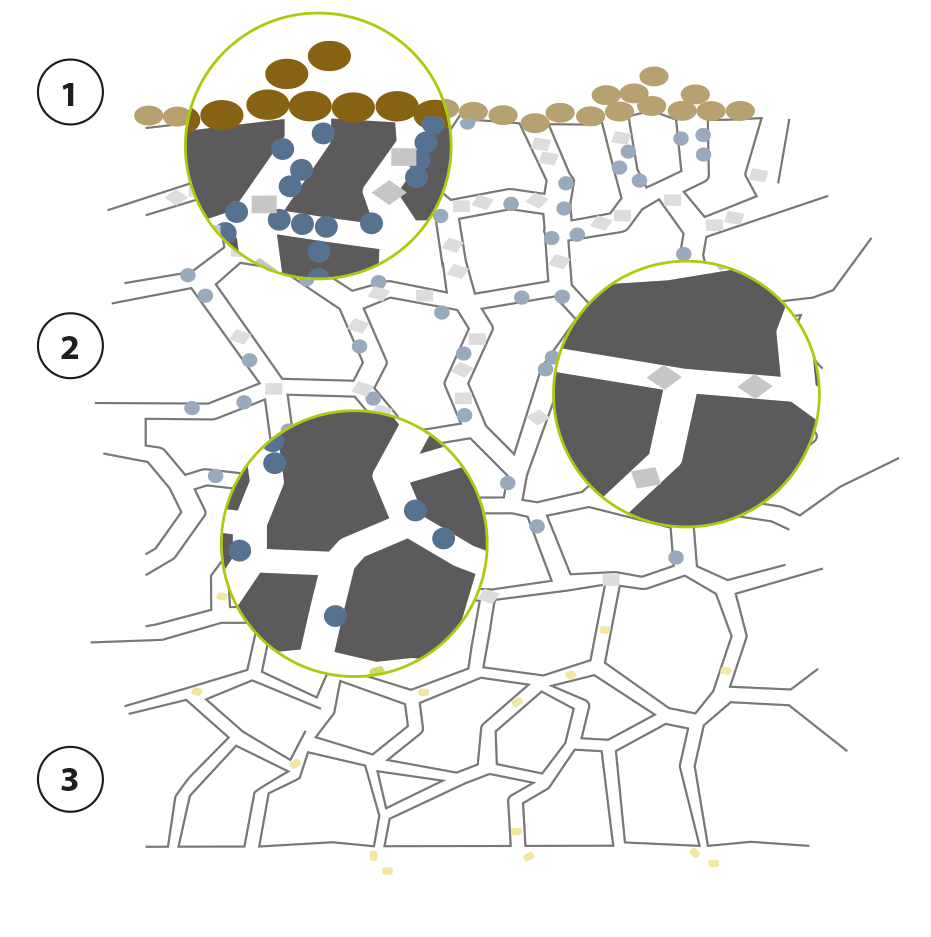

Depth filtration

The increased depth of the Carbon Pads allows multiple stages of filtration.

1. Larger solids are held on the surface of the pad.

2. Smaller solids are trapped within the structure. The structure has a very high volume of internal pores so can hold a high degree of solids.

3. The internal structure gets tighter the further you travel through the pad ensuring even the finest solids are trapped.

Active Oil Treatment

Active carbon and specialty adsorbent powders are built into, and held, within the structure of the depth Carbon Pads. These active powders remove and reduce metallic ions, soaps, color, odor, off flavours and even finer particulates suspended in the oil. Without the removal of these extra contaminants the oil degradation will accelerate.

After a single pass through the Carbon Pads the oil is ready to be returned to the frying vat.

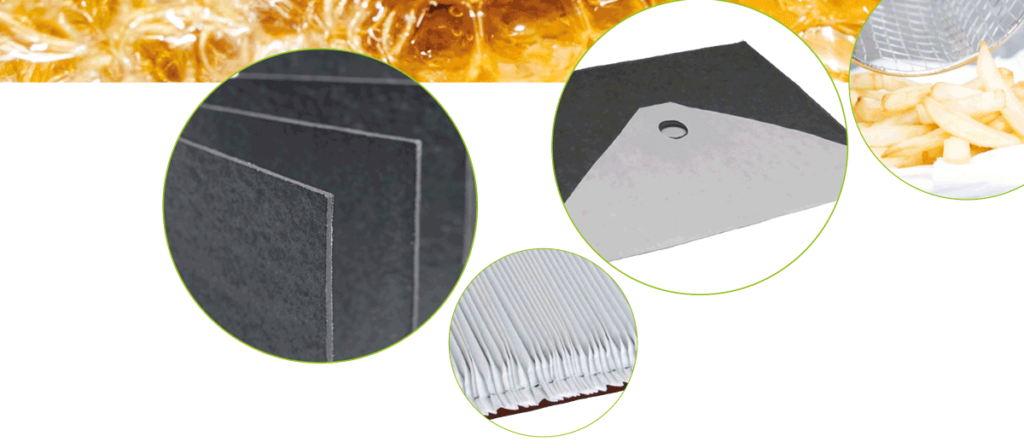

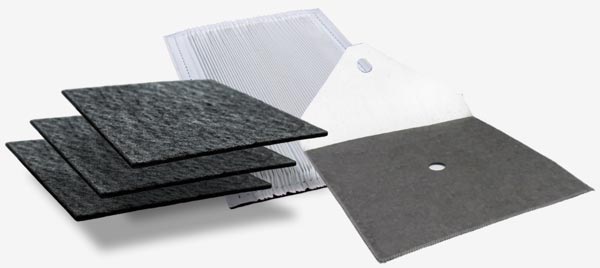

| Product | Description | Best use | |

|

SuperSorb® Carbon Pad | Filter pad with activated carbon and specialty adsorbents, built into a depth of cellulose fibers. | All frying oil filtration applications requiring a flat pad. |

|

SuperSorb® Pleated Carbon Pad | Pad with activated carbon and pleated pre-filter. | 2 in 1 filter for heavy duty applications. |

|

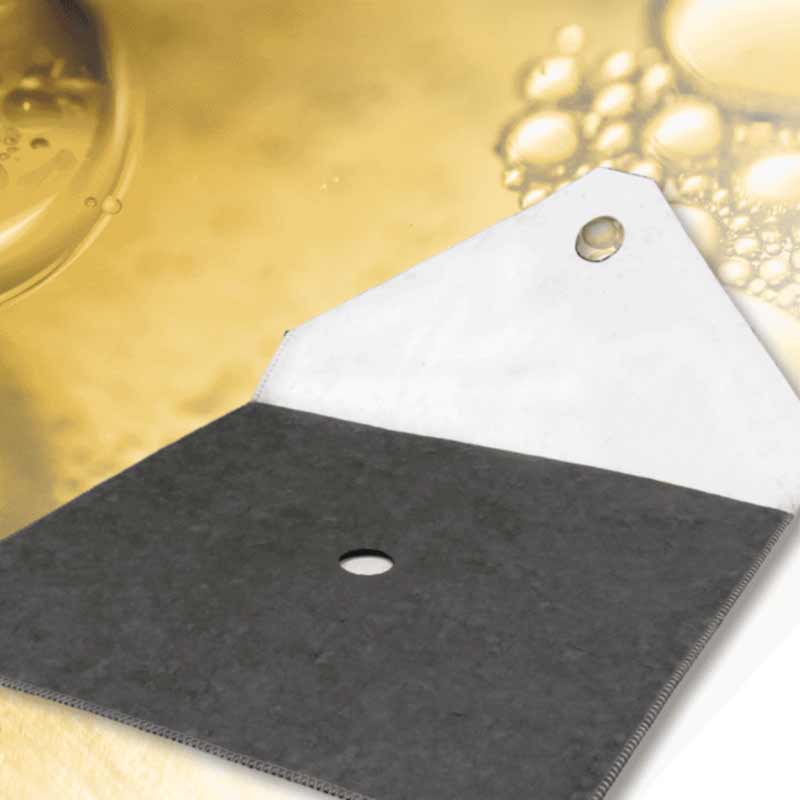

SuperSorb® Carbon Envelope | Filter pad built into an envelope format. | For fryers that require envelope type filters. |

SuperSorb® Carbon Pads and Envelopes work with all built-in and portable frying oil filtration systems. No need to add additional powders as these are already built into the depth of the Carbon Pads and will not wash out.

Filter Media

SuperSorb® Carbon Pads

3 different types of SuperSorb® Carbon Pads in different sizes are available, designed for most common deep fryers on the market. The three Pad types Carbon Pad, Pleated Carbon Pad and Carbon Envelope differ in terms of frying oil filtration requirements and fryer model.

Portable Filtration Machines

Model LS-2 Portable Filtration Machine

The Model LS-2 60# and 100# filter machines are constructed of Anodized Aluminum. Anodizing provides a reacted finish that is integrated with the underlying aluminum for a total bonding and unmatched adhesion. Designed to filter 60 Lbs. / 115 Lbs. of oil. Only available in the USA.

Warranty Registration

What is important in your food service operation?

When you chose any product for use in your food service operation, these are just some of the concerns many operators have when making the decision of “why”? At FILTROX, we ask exactly that hard question. Specifically, what is most important to your operation and why?

We operate on the premise that we are a solution provider for our customer’s frying oil filtration needs. Your long-term satisfaction is our goal. You’ll have the results to prove it: cleaner oil, longer lasting, less usage, greater savings – plus consistent quality food.

SAVINGS

With SuperSorb® Carbon Pads, your frying oil is filtered cleaner. So it lasts longer, you use less, save more, and have more consistent food quality. A single pass and no polishing on every fry pot saves time and money. Purely and simply, it’s a win-win for you, your customers and your bottom line.

COMPLETE SOLUTIONS

FILTROX offers a complete line of frying oil filtration media and equipment, including SuperSorb® Carbon Pads. We operate on the premise that we are a solution provider for our customer’s oil filtration needs. Your long-term satisfaction is our goal. We value the partnership and loyalty of our customers and look forward to bringing continued innovation in consistent food quality.

UNIQUE TECHNOLOGY

Our oil filtration technology is a unique innovation in oil filtering, developed specifically for treating edible frying oil. The unique combination of specific activated carbon and cellulose fibers, along with other activated adsorbents, with billions of tiny pores physically removing contaminants from your oil.

ENVIRONMENTALLY FRIENDLY

Our SuperSorb® products extend oil life and reduce the number of oil changes needed in foodservice operations across the globe. And this in turn is reflected in less packaging waste. But we did not stop there. Our engineers and product development teams worked tirelessly to create a filter that’s biodegradable. SuperSorb® is BPI Certified.

The Carbon Pads are made primarily of cellulose, a naturally biodegradable product. Our team partnered with the Biodegradability Products Institute (BPI) to complete necessary testing of our frying oil filtration products to achieve BPI certification. As a result of this testing, SuperSorb® products were found to comply with the specifications established in the American Society for Testing and Materials standard ASTM D6400 and/or D6868 in accordance with the terms and conditions of the International Biodegradable Products Institute, Inc. Licensing & Certification Program for Compostable Products (BPI Certification). We are proud to do our part in reducing global waste and producing biodegradable products. Visit the BPI page and see the certified products

EASY TO USE

Ready to use in any type of commercial fryer! The easy-to-use and operator safe pads can be installed and replaced in a few simple steps. They are much easier to use than traditional filters, meaning a faster, cleaner, hassle-free process for your back-of-house team.

NSF APPROVED

Our SuperSorb® frying oil filtration products are NSF approved components. That means products have been rigorously tested to comply with all standard requirements to protect humans health and the environment. Visit the NSF page and see our listed products.

MAINTAIN FOOD QUALITY

Experience more consistent, higher quality fried food. The proof is in the taste and the profits. SuperSorb® Carbon Pads are designed to perform depth filtration, removing particles down to the nano-range of 0.5 micron and to clean-treat the frying oil. All this in a one-step process. Your oil is cleaner, it lasts longer, the food you fry tastes better. At FILTROX, “filtration is what we do, and people are why we do it.

EXPERIENCE

Filtercorp introduced SuperSorb® activated carbon depth filtration for frying oils to the food industry in 1987. Over the years, we have been proven to perform in over 50,000 food service operations out-performing other types of oil filtration media. Filtercorp’s SuperSorb® Carbon Pad has helped food service operators and food processing manufacturers around the world serve healthier, better tasting fried foods.

TECHNICAL SUPPORT WORLDWIDE

FILTROX’s worldwide distribution network and comprehensive technical and marketing support services will help you build a frying program that improves productivity and increases food service and processing profitability. When you begin to expect more from your frying program, talk to us. We’ll help you get the most out of it.

INDUSTRY SEGMENT ANALYSIS

Our regional local filtration specialists are capable of organizing and conducting a comprehensive Fry Study to evaluate an operator’s frying program.

Find Your Filter Pad

FILTROX carries SuperSorb® filters for most fryer makes and models. Our filters are built to fit fryers from 18 different manufacturers! Each filter is designed specifically for each operation’s needs, whether high volume or low volume.

Use the drop-down menu below to find your filter.

|

Select a Manufacturer from the dropdown ⇒ |

|

Order your Free Sample

New to SuperSorb®? Request a free sample! SuperSorb® is available for most fryer makes and models.

Sample Request Form

Frequently Asked Questions

Here you will find relevant information and assistance for the optimal deep-frying process. We always strive to offer you the best possible service. For this reason, our FAQ area is continuously being expanded and developed. Feel free to contact us if you have any questions, suggestions or requests.

FAQ’s

How do I know which filter to use?

From our FILTROX website, use our “Find Your Filter” tool to find the right filter for your fryer.

How do I know when to discard my oil?

Oil discard point can be determined several different ways. Color and clarity of the oil in the fryer, off flavors of the food, smoking oil in the fryer, etc. Please feel free to contact FILTROX for more details. Contact form

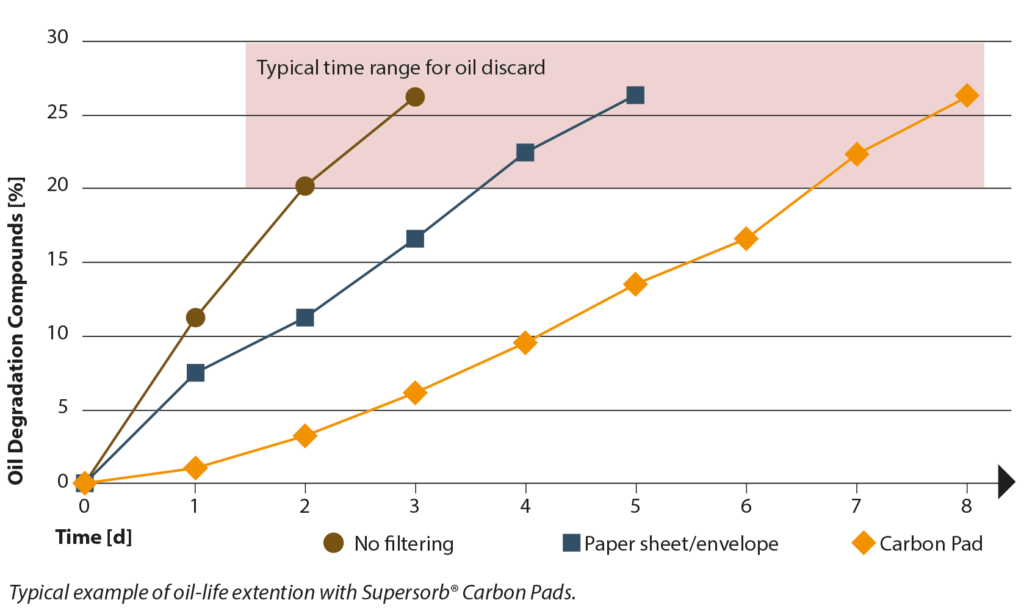

How long should my frying oil last when using SuperSorb® Carbon Pads?

That depends upon what you are frying, how often you fry, the type of oil being used and your commitment to quality. Please feel free to contact FILTROX for an analysis of your oil quality today. Contact form

Do I need to use any filter aids (fry filter powder) when using a SuperSorb® Carbon Pad?

No, the unique combination of activated carbon, cellulose fibers, along with other activated absorbents, with billions of tiny pores physically remove containments from your oil without using powder.

How long do SuperSorb® Carbon Pads last in my fryer?

SuperSorb® Carbon Pads are designed for a single day’s use. Simply install a fresh pad each day to maximize your savings.

Can the SuperSorb® Carbon Pads get wet?

No, the SuperSorb® carbon pad is construction of billions of tiny pores. This natural absorbent construction will capture and trap moisture as well as debris. Make sure your filter pan is clean and dry when installing a new filter pad.

Will the Carbon Pads work with any type of cooking oil?

Yes.

How often should I filter my oil when using SuperSorb® Carbon Pads?

This depends on the type of foods you fry and how often you fry. However generally speaking the more often you filter your frying oil, the cleaner the oil will be.

How many filter pads are in a case?

There are 30 SuperSorb® Carbon Pads to a case. One case is one month’s supply.

Does FILTROX provide assistance during installation and startup?

Yes, please feel free to contact FILTROX or one of our regional offices to receive assistance today. Contact form

Does FILTROX provide free samples to try?

Yes, please feel free to contact FILTROX or one of our regional offices to receive your samples today. Sample request form

Can depth filter media be cleaned or washed?

In general no. Due to the nature of the structure that traps the particles, these particles are difficult to get released or removed.

Can the depth filter media be classified to remove a given particle size like 1 µm or 0.5 µm?

For a given application and specifically targeted particle size a chosen depth filter media can be used to remove this range. But the process conditions must be set-up to match that application. For example, if you double the design flow rate for that application, the depth filter media will allow this, but there is a high risk of the particle size you want to retain being pushed through.

The Doe’s & Don’ts of Frying Oil Management in Daily Business

With these simple tips you can optimize your cooking oil management.

Dos & Don’ts of Frying

- Keep fryers set at proper frying temperature

- Use your skimmer and keep the fryer free from floating french fries, nuggets, etc.

- Add make-up oil often. Do not allow the fryer to be unter-filled.

- Discard only on the basis of a quality standard. Use a color test kit, or similar.

- Filter twice a day, every day.

- Cover fryers after closing kitchen.

- Designate one fryer for fries only.

- Turn on fryer too early! (One-half hour before frying is proper.)

- Dip fried foods that have cooled in the fryer a second time.

- Turn up thermostats and overfill fry baskets to speed up frying..

- Let food sit in baskets over the fryer.

- Use soap to clean deep fryer.

- Stir, agitate, or aerate shortening unnecessarily.

- Salt over fryer or deep fry bacon or sausage in the kettle.

Brochures and Flyers

|

FRYING OIL FILTRATION SOLUTIONS |

Instruction Manuals

General installation instructions

How to install the filter pads into a specific fryer

Support Bulletin

| ► O-ring gaskets for suction tube maintenance |

Manuals for Portable Filter Machines

| ► LS-2 User Manual |

| ► Installation instructions: how to insert a Carbon Pad into the LS-2 filter machine |

Helpful Tools

| ► Monthly Frying Oil Log |

Technical Data Sheet

| ► SuperSorb Carbon Pads |

| ► LS-2 filter machine |

FILTROX AG (Headquarter)

Moosmühlestr. 6

CH-9001 St.Gallen / Switzerland

Phone: +41 71 272 91 11

sales@filtrox.com

FILTROX France s.a.r.l.

18 rue Buffon

F 21200 Beaune / France

Phone: +33 6 74 16 24 03

france@filtrox.com

FILTROX Carlson Ltd UK & Northern Europe

Butts Mill

Barnoldswick

Lancashire

BB18 5HP / United Kingdom

Phone: +44 1282 811000

Fax: +44 1282 811001

filtrox.UK@filtrox.com

FILTROX Southern Europe

Calle Can Vinyalets, 15

08130 Santa Perpètua de Mogoda / Spain

Phone: +34 934 626 700

filtrox@filtrox.es

FILTROX North America, Inc

5506 6th Ave S. Suite 107

Seattle, WA 98108 / USA

Phone: Toll free 800 473 4526

Phone: +1 425 820 4850

Fax: +1 425 820 2816

info@filtroxnorthamerica.com

FILTROX Latinoamerica S.A. de C.V.

Prolongación Recursos Hidráulicos 22, Lote A

La Loma, Tlalnepantla de Baz, CP 54060

Estado de Méxcio / Mexico

Phone: +52 55 2628 1691

info@filtrox.com.mx

FILTROX Asia-Pacific Pte Ltd

25 International Business Park

#02-14 German Center

Singapore 609916 / Singapur

Phone: +65 9880 1651

sales_apac@filtrox.com

FILTROX (Shanghai) Filtration Systems Co., Ltd

Room 406, Qinghewan Road #980

Qingpu district

Shanghai 201717 / P.R. China

Phone: +86 021 5922 7601

sales_apac@filtrox.com

Your local SuperSorb® distributors in the USA and Canada

General Contact Form

| SuperSorb® established by Filtercorp USA in 1987. |