SUSTAINABLE FILTRATION SOLUTIONS

Sustainability at FILTROX means: Think Sustainably, Act Sustainably

Our lives depend on this wonderful planet Earth that we inhabit, that we use intensively and take from. This is exactly why we have to use resources in a smart way and ensure that they remain available for the next generation and beyond. It is time for everyone to make their own contribution.

Based on the principle “Leave no one behind”, the UN have set seventeen challenging sustainability objectives for the year 2030 to attain ecological, social, and economic development. This is to ensure that future generations also have the opportunity for a good life.

Inspired and motivated by this challenge, we at FILTROX are following individual objectives, which we have detailed in our sustainability plan 2030. In nine different areas, we are setting ambitious goals, which we will implement step by step in cooperation with our partners. Among other things, we are working on reducing our negative impact on the environment, on being a sustainable and safe employer, while simultaneously making a commercially successful contribution.

Join us on our way. We would be more than happy to show you what we have already achieved and what sustainability projects we will be working on in future.

| Our Sustainability Report 2022 | Our Sustainability Report 2023 | Our Sustainability Report 2024 |

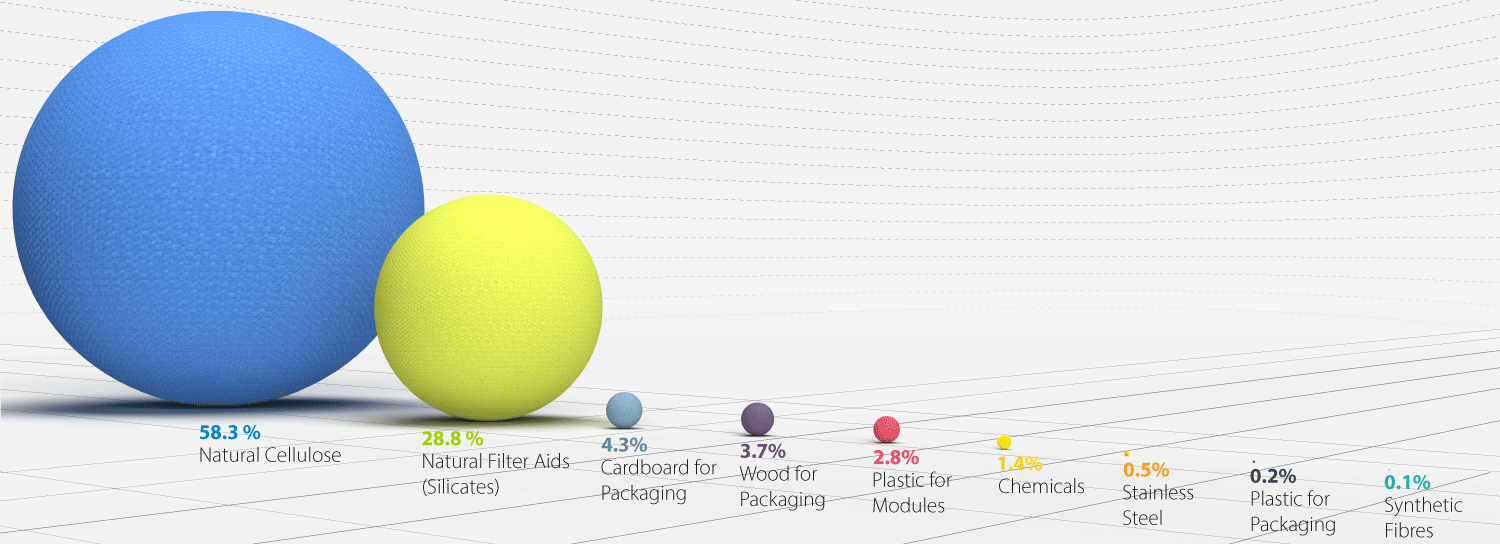

95 % Natural!

Our raw materials are 95 % natural!

The individual components for our filters are virtually all sourced naturally. Cellulose and naturally occurring minerals are the main components, such as Diatomites or Perlites. Considering our annual global consumption of raw materials, 95 % are from natural sources. And considering all the raw materials required for manufacture and production, regenerative cellulose materials make up the largest share at nearly 60 %. We primarily use raw materials like wood, plastic, and stainless steel for creating packaging, crafting modules, and manufacturing filter equipment.

Overview of all raw materials required for production.

Overview of all raw materials required for production.

A natural, sustainable sourcing plan

A natural and sustainable supply plan

Compared to the virtually inexhaustible supply of minerals from fossilized diatoms or perlites, cellulose derived from trees is an incredibly valuable raw material. That is why we use cellulose from sustainable forestry for our filter sheets. 99.5% of the total cellulose processed comes from suppliers with at least one sustainability certificate such as FSC. We are fully aware of our responsibility towards the environment and are therefore working with suppliers who share our values. Please see our Responsible Sourcing Policy

The reforestation of processed trees is particularly close to our hearts, as the cellulose is the main component of our products.

░OUR SUSTAINABILITY GOALS FOR 2030.

We produce 100 % of our products from raw material sourced from supplier with sustainability certification.

It is an unavoidable fact that we are unable to produce anything without water, electricity, and gas. However, we are taking steps to ensure our energy and water use is kept as low as possible. And we are continuously investing in our plants to reduce our consumption.

Dry season

The drying process

We efficiently use most of the energy in manufacturing filter sheets to dry the wet mixture of cellulose and minerals, starting with vacuum drying on a wet wire. The second step consists of drying the filter media in an continuous oven. At the end of the manufacturing process, this results in completely dried filter sheets. Therefore, we pay particular attention to this step of the process and are continuously looking for improvement potential in processes and technology. Measures including improved vacuum pumps, insulation of the drying oven, improved ventilation, and optimization of the burners have yielded positive results for our energy footprint. By refurbishing the drying ovens at all three production locations, we have been able to reduce our electricity consumption in recent years by 10 %, and our gas consumption by 20 %.

Cellulose mixture before drying.

Cellulose mixture before drying.

Well insulated drying oven after refurbishment.

Well insulated drying oven after refurbishment.

Back to start

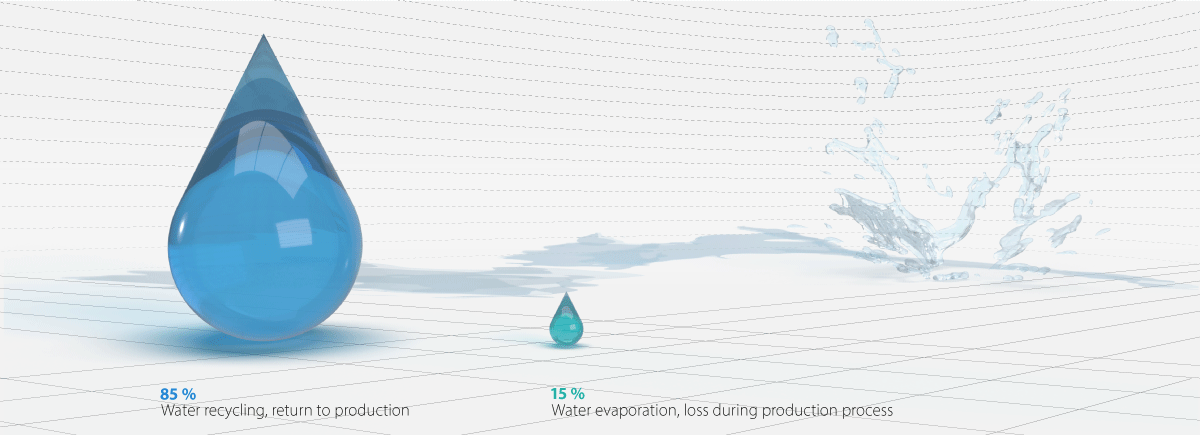

A new beginning for used water

Our three production sites are each equipped with a water recovery system. Approximately 85 % of the water used is recycled and fed back into the production process. Most of the remaining 15 % vaporize during the production process. We have been able to reduce consumption by 6 % at our site in Mexico simply by optimizing the production process.

Solar power

Our own ecological solar power

We are gradually installing solar panels in our production sites in Mexico and UK. The first installations in Mexico have already been completed. With the renovation / new construction of the production facility in Barnoldswick (UK), a solar energy system is also planned there.

░OUR SUSTAINABILITY GOALS FOR 2030

We reduce the CO2 emissions generated by our production process per square meter of produces and sellable filter media by 33 % across all production sites compared to 2023.

Maximum minimization

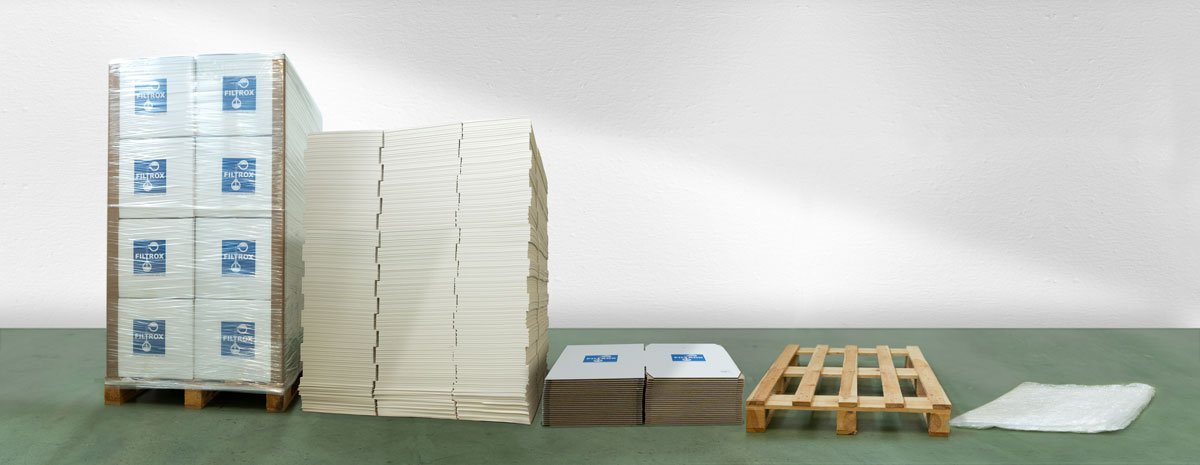

As much packaging reduction as possible

We reduce the amount of packaging material for our filter sheets to the bare minimum. Just enough is used to ensure that the delivery arrives at the customers in perfect condition and undamaged, and complies with the stipulated hygiene guidelines. Most of the packaging is made up of cardboard boxes, which can be recycled. Plastic and synthetic materials only make up 2.7 % of the total weight of the packaging material.

Comparison of a pallet with all its packaging: proportion of filter sheets, cardboard, pallet, plastic

Comparison of a pallet with all its packaging: proportion of filter sheets, cardboard, pallet, plastic

Make new from old

Cardobard upcycling

By upcycling cardboard boxes no longer used, we have been able to reduce cardboard waste by 75 % in Barnoldswick (UK). With our own punch press, we are able to process cardboard, which was directly recycled previously, and turn it into new, smaller boxes. These can be used to ship small parts and samples.

Cardboard boxes for sending samples made of leftover cardboard.

Cardboard boxes for sending samples made of leftover cardboard.

░OUR SUSTAINABILITY GOALS FOR 2030

We use more than 99 % of recyclable or recycled packaging material.

Collect, separate, and recycle

We collect offcuts and rejects from the production of filter sheets in separate areas. The majority of offcuts are shredded and reused in the production of new filter sheets. We send the remaining materials to cardboard manufacturers. There, they are recycled into new cardboard products.

Offcuts from sheet production are collected and recycled.

Offcuts from sheet production are collected and recycled.

Other materials

In addition, we carefully separate out all other materials and waste, which are then taken to collection points so they can be recycled.

Recycling collection point at St.Gallen site

Recycling collection point at St.Gallen site

░OUR SUSTAINABILITY GOALS FOR 2030

We recycle more than 95 % of all byproducts resulting from our primary production process.

Regardless of whether it is a filter sheet, module or filter apparatus, we make sure that our products are not only sustainable in production, but are also sustainable themselves.

Inner values

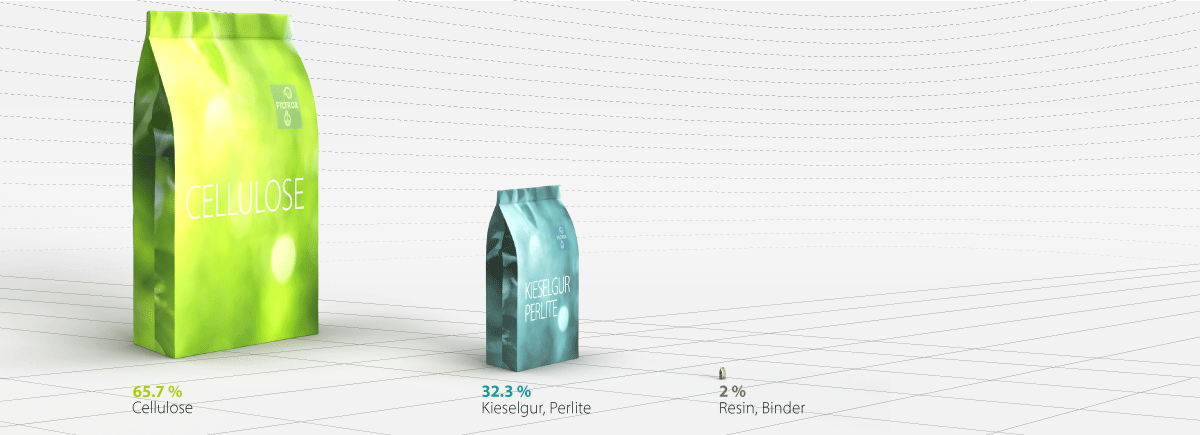

The Inner Values of our Filter Sheets

Inner values are key? Of course! The composition of the formulations will vary from filter sheet to filter sheet. However, the individual components remain essentially unchanged. Our filter sheets feature a composition, consisting of an average of 65.7% cellulose and 32.3% Kieselgur or Perlite, ensuring exceptional quality and performance. The remaining approximately 2 % are the necessary bonding agents (resins), which bind the fibers of the filter sheet together.

So, when it comes to being natural, our filter sheets are ahead of the game.

Outer strength

We produce filtration equipment using high-quality stainless steel components, ensuring optimal performance for our filter media. Continuous development, for example to reduce the waste through less drip-loss, is part of a constant optimization process. Due to high-quality raw materials, the durable construction, and the small amount of movable parts, our filter equipment has a very long service life. 30 years is very common and not seldom we see plants in operations that are more than 50 years old.

░OUR SUSTAINABILITY GOALS FOR 2030

We will develop a climate positive depth filtration solution to support our customers in working with an environmentally friendly mindset.

Depth filtration is a very energy-efficient process to remove particles from liquids. It is energy-efficient because the liquid is siphoned through the filter sheets by differential pressure alone. Operation and cleaning only require very few resources and limited use of chemicals.

As our customers’ applications are in sensitive areas such as life science, beverage, and food production, we are truly dedicated to working with our customers and taking the requirements of our filter solutions seriously, while continuously improving the technology.

░OUR SUSTAINABILITY GOALS FOR 2030

We reach 30 successfully installed projects with a significant and measurable positive effect on our customers sustainability goals.

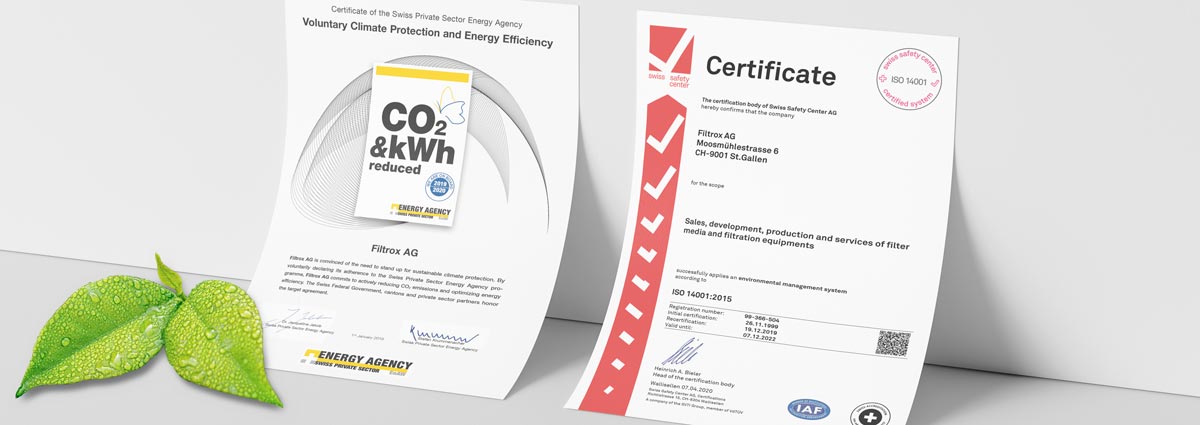

ISO 14001

Our site in St.Gallen has been ISO 14001 certified for many years. This means we are working in compliance with controlled guidelines as set out in our environment management system.

We are currently working on expanding the certification to our other production sites. The next step is the certification of our production facility in Tlalnepantla (Mexico).

ISO 14001 Certificate Site in St.Gallen

CO2 reduction

Climate protection is important to us. That is why we are happy to voluntarily do more to protect the basis of our existence. With the projects CO2 Voluntary Climate Protection (Switzerland) and CCL Climate Change Levy (UK), we are committing to thinking sustainably in the long term and acting in a sustainable manner. We are working on reducing our CO2 emissions even further and towards ongoing optimization of energy efficiency.

EcoVadis

We are part of the EcoVadis program, which helps us identify areas for improvement and drive continuous progress. These important milestones highlight our commitment to sustainability and responsible business practices.

EcoVadis is a global sustainability rating platform that evaluates companies on a range of environmental, social, and ethical criteria. Their comprehensive assessment process looks at our policies, practices, and performance across a variety of areas, including environmental impact, labor and human rights, and business ethics. ecovadis.com

░OUR SUSTAINABILITY GOALS FOR 2030.

We are the leading company in our niche when it comes to certifications and ratings of sustainability.

Trees for the future

We actively support initiatives worldwide and contribute to various impactful projects beyond our organization.

Anyone who uses natural products is also responsible for making sure they are used in a sustainable manner. We take responsibility for promoting the sustainable use of natural products and we actively ensure that trees and forests are protected, nurtured, and replanted.

Let’s green the planet – Treedom

Together with the Treedom project, we are making the planet greener. At the same time, we support local farmers who plant the trees for us. The harvested fruits belong to the farmer, he/her can use them as a food resource or support for their income. As our planted trees grow, they will absorb CO2, protect the soil and the biodiversity of the characteristic area.

Read the FILTROX Treedom report 2025

Discover our FILTROX forest here on Treedom

![]()

![]()

![]()

Small steps

We are convinced that, when added together, many small steps amount to making a significant contribution. Examples of this are the already completed switchover from plastic to glass bottles, the reduction of one-way plastic products, or the ongoing change to using LED lamps and electric forklift trucks. These steps also have a positive impact on our environment in future.

Our organization takes actions, measures their success, controls their implementation and continuously develops them. Our primary goal is to ensure safety and quality and to ensure future development. To this end, we have created specific global policies to guide our activities.

| Environmental Policy Statement | Occupational Health and Safety Policy Statement | Quality Policy Statement |

Our own initiatives

Here you can find events organized and carried out by our sales offeces and production sites worldwide.

FILTROX Southern Europe

On September 5th, FILTROX Southern Europe and France participated in the activity “Sea, source of life”. The event was managed by Greenevents, a company specialized in organizing sustainable experiences.

During 1h 30’ we searched for hidden treasures of the sea while cleaning up the beach. Then we shared the treasures and discussed about the waste in the marine ecosystem. In the second part, we completed the cleaning doing water sports while answering questions about the impact that humans generate in the marine ecosystem. The group that collected the most waste and got most correct answers received a gift (a bottle of ecologic cava).

FILTROX Asia Pacific

The team participated in the OneMillionTrees movement in Singapore. The movement aims to restore nature back into city through the planting of a million more trees across Singapore over the next 10 years. Facts: To date, the movement have successfully planted 560,317 trees across Singapore! The team have their hands dirty in the 34 °C with lots of fun and sweats (June 2023)

FILTROX Mexico

Our FILTROX Team in Mexico and their families planted trees in Santiago Tianguistengo. About 40 persons participated in this wonderful activity and planted about 350 trees in a half hectare plantation. (August 2022)

Headquarters Switzerland

The team at the headquarters in St.Gallen in Switzerland worked in a small nature reserve near our FILTROX site – the Bildweiher. This area, in the middle of an industrial and residential area offers many amphibians and birds protection and shelter. Under the guidance of a small team from the local nature conservation association, we gathered the cut reeds into large piles, cut back trees and bushes and stacket them into piles (also for small animals and amphibians as winter quarters) and added visual aisles. (September 2022)

The operations team at in St.Gallen has taken care of the environment around the company premises. Equipped with sacks, gloves and tongs, they have cleared the entire area of rubbish lying around. (August 2022)

FILTROX ASIA PACIFIC

executed a sustainability project day with programme focus on Upcycling. The goal was to educate through the hands-on process of upcycling. All participants brought home a product that they created themselves, but also be inspired to rethink the possibilities of the waste that they throw away in daily lives and play a part to advance sustainability agenda for the world.

Main elements weaved into programme:

- Alignment with UN Sustainable Development Goals/Sustainable Singapore Blueprint

- Integration of learnings – thinking, environmental knowledge and team building

- Upcycling Methodologies, Innovation and Design thinking

- Alignment with international efforts Towards Zero-Waste

- Hands-on activity. Creating coaster mats from old t-shirts and LED design lamps with upcycled wine bottles

FILTROX Carlson in Barnoldswick UK,

participated in the Bike2 work scheme.

About Bike2Work: “Cycling has many benefits. From improving health and fitness to increasing energy and positivity. Not to mention reducing environmental pollution.”

FILTROX China

“Plastics Are Forever”. Under this motto, our FILTROX China team together with Shanghai distributors executed a sustainability project day with focus on “white pollution. Part of this event was a hands-on activity on upcycling possibilities of plastic bags and packages. Using electric iron, we transformed them into small bags, which we can put our coins and keys and other small stuffs into it, so it can be used in our daily lives. We realize: it is easy to be done at home.

Food for thought

Aside from the handmade bags, we learned a lot and took away a lot of food for thought. Plastics are around us everywhere in our daily lives, such as plastic bags , plastic bottles, they make our lives more convenient, however we do not know where they are going after being thrown away. In this session, we learned that only less than 40% are recycled, most are going back to the ocean, soil, with huge environment impact as they are non-biodegradable. They seriously affect our living environment. We need to rethink how we deal with plastics in our future lifes.

░OUR SUSTAINABILITY GOALS FOR 2030.

We will have one project in each FILTROX location worldwide every year to support global sustainability goals.

The Action Level „People“ aims to ensure equal opportunities and non-discrimination for all employees and stakeholders regardless of age, skin color, ethnicity/race, gender, gender identity, marital status, pregnancy/maternity, national origin, sexual orientation or religion. We strive to ensure that diversity and equality guidelines are well-known and respected across all our locations.

We provide safe and attractive workplaces ensuring health and safety as a top priority for all employees and stakeholders. And of course, we implement global Human Rights standards and full conformity with local labor rights. Corruption and bribery are not tolerated. We set a strategy, outlining how to work with suppliers to prevent child labor, forced labor, sexual harassment and excessive working hours or indirectly achieve fair remuneration according to local regulations.

Our ongoing implementation of IT security guarantees protection of personal data of all our employees, partners and stakeholders.